International elevator manufacturers are not the only market players who are entering China, the world’s largest market for elevators, domestic manufacturers are also growing rapidly and competing to introduce products. Hitachi stepped up to the challenge by developing competitive elevators that are manufactured in China and launched them in 2010. These elevators have become Hitachi’s flagship products, with a full lineup of elevators extending from high-speed to machine-room-less models, which make up approximately half of all orders by volume. Their development in China is helping to provide high-speed and greater-capacity elevators in ever-larger buildings. The elevators feature a compact design to satisfy customers who want to shrink the amount of space occupied by the elevators, and also to reduce power consumption by utilizing regenerative converters and LED lighting to satisfy requirements for energy efficiency.

Product Development Department, R&D Division, Hitachi Elevator (China) Co., Ltd. He is currently engaged in the development of elevator products.

Components R&D Department, R&D Division, Hitachi Elevator (China) Co., Ltd. He is currently engaged in the development of elevator control systems.

Product Development Department, R&D Division, Hitachi Elevator (China) Co., Ltd. He is currently engaged in the development of machine-room elevator products.

Product Development Department, R&D Division, Hitachi Elevator (China) Co., Ltd. He is currently engaged in the development of machine-room-less elevator products.

Product Quality Assurance Department, Quality Assurance Headquarters, Hitachi Elevator (China) Co., Ltd. He is currently engaged in the examination and quality control of elevator products.

Technology Department, Hitachi Elevator Motor (Guangzhou) Co., Ltd. He is currently engaged in the development of elevator traction machines.

Product Development Department, R&D Division, Hitachi Elevator (China) Co., Ltd. She is currently engaged in the development of electric parts for elevators.

Elevator Development Department, Global Development Division, Global Elevator & Escalator Division, Building Systems Business Unit, Hitachi, Ltd. He is currently engaged in the development of elevator products.

Fig. 1—Elevator Sales in the Chinese Market.

The graph shows the total number of elevators sold by major manufacturers between 2008 and 2015 (based on research by Hitachi).

The graph shows the total number of elevators sold by major manufacturers between 2008 and 2015 (based on research by Hitachi).

ALONG with rapid economic development in recent years, China has experienced ongoing urbanization that extends beyond the major cities to its small- and medium-sized cities. The continued construction of large shopping complexes and housing in these cities is driving a rapid expansion in the country's elevator market (see Fig. 1). In 2011, China led the world both in the number of elevators produced and in the number in use.

The market has become a focus of attention for international elevator manufacturers, with competition for market share growing fiercer every year.

Vendors are continuing to launch new products in response to the requirements for elevators as they change along with changes in the wider world.

Amid ongoing urbanization, high-rise construction projects are getting larger. As this is driving continued growth in the market for the high-speed elevators required for these buildings, elevator development strategy is prioritizing higher speeds and capacities.

In response to builders wanting to make more efficient use of space, there has been rapid growth in demand over the last few years for elevators that do not require machine rooms. Demand grew at an annual rate of approximately 20% between 2007 and 2015, increasing from 19,300 units/year to 83,500 units/year. The use of machine-room-less elevators is expected to continue to spread to the extent that they will become the mainstay of the market over the next decade.

The rise in public concern about elevators over recent years also extends beyond safety to include things like the visual and tactile qualities of displays and buttons, ride comfort, waiting times, and accessibility for the disabled. As a result, along with placing top priority on safety and reliability, intelligent features and designs that proactively anticipate unconscious human behavior are among the objectives of Hitachi's product development. Hitachi is also working on offering solutions that take account of how to transport people most efficiently by making elevators better at transporting users during busy times to ensure that the elevators provide a quick and comfortable way to move around the building.

China is experiencing rising wages as well as demand for shorter construction schedules (the time from breaking ground to completing a building). As elevator installation and commissioning takes place within this period, making these tasks more efficient has become one of the challenges for new product development.

Poor maintenance is believed to be the main cause of elevator accidents in China, with numerous maintenance companies involved in the elevator maintenance business and wide variations in service quality. To improve this situation, Hitachi is drawing on the benefits of having the manufacturer handle maintenance and is utilizing network technologies and information-based techniques to provide more efficient maintenance and safe elevator operation as well as seeking to bring more intelligence to management practices.

Buildings make up more than 28% of China's total energy use, with the number of buildings continuing to grow year after year. Accordingly, the Chinese government set targets for reducing energy consumption between 2006 and 2010 in its 11th five-year plan and requested that the relevant parties take steps to save energy. Given that elevators are part of a building's facilities, there are growing demands for making them more energy efficient.

Hitachi has served the rapidly growing Chinese market by selling two different ranges of elevators, namely high-end models exported from Japan and standard models made in China. However, in response to the arrival on the market of high-end Chinese-made elevators from competing manufacturers beginning around 2007, Hitachi set out to develop a high-end version of its own Chinese-made elevators.

The main control systems in these elevators made greater use of Japanese-developed systems and adopted a traction machine made by a Hitachi company (Hitachi Elevator Motor (Guangzhou) Co., Ltd.). The new models conformed to Hitachi's global standards* in terms of basic control performance and safety design and featured improved ride comfort and reliability. The design of the elevators was also upgraded and optional features were made available. These new Chinese-made elevators went on sale in 2010.

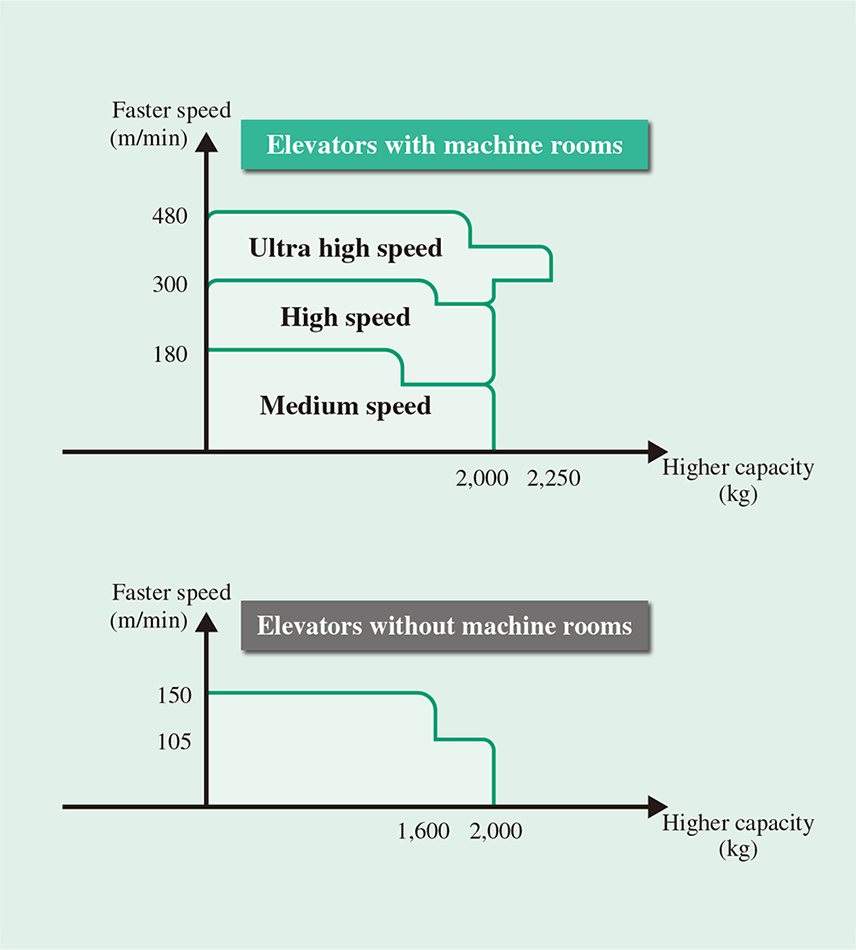

Fig. 2—New Product Range of Models Manufactured in China.

The new product range offers models with faster speeds and higher capacity to satisfy market requirements.

The new product range offers models with faster speeds and higher capacity to satisfy market requirements.

The first model to go on sale was an elevator that requires a machine room, and was targeted at the volume end of the market. Energy efficiency features include LED lighting in the elevator car and a regenerative converter, and it also uses new group control systems for more efficient transportation.

This was followed by the launch of high-speed and ultra-high-speed models designed for faster speed and higher capacity.

Following the development of a traction machine with higher capacity than before, these elevators now have a maximum carrying capacity of 2,250 kg, a maximum speed of 480 m/min, and a maximum travel distance of 330 m. These features satisfy the requirements of a market characterized by larger and taller buildings.

For the rapidly growing market for elevators that do not require a machine room, as described above, Hitachi also launched a machine-room-less elevator that features a maximum carrying capacity of 2,000 kg, and a maximum speed of 150 m/min. In response to market demand, this model makes efficient use of space thanks to enhancements that include the development of a new thin-profile traction machine and smaller safety equipment.

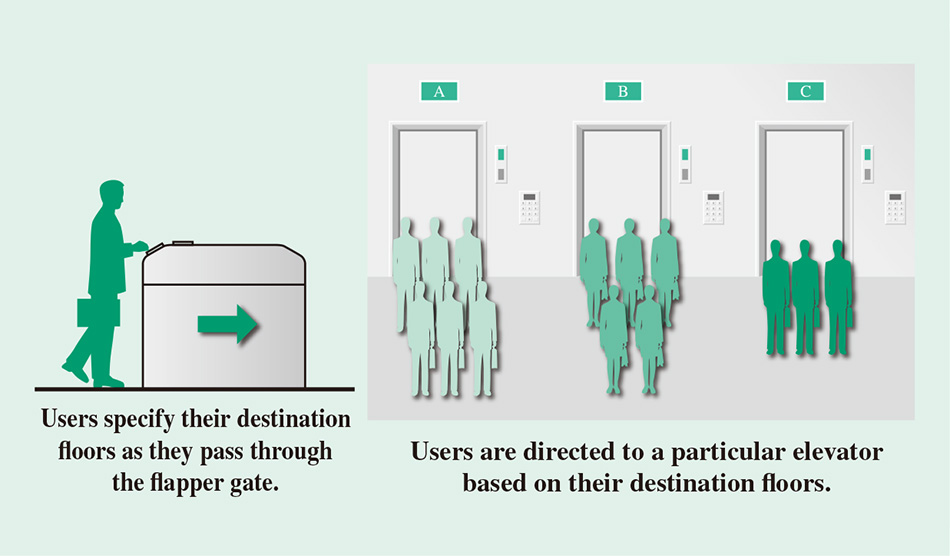

Alongside this expansion of the product range, Hitachi has also been making improvements to operational quality and maintenance efficiency, including the incorporation of a destination floor reservation system, and remote monitoring of the elevator using equipment specifically designed for this purpose.

Through these measures, Hitachi has established a product range that covers almost all market requirements (see Fig. 2).

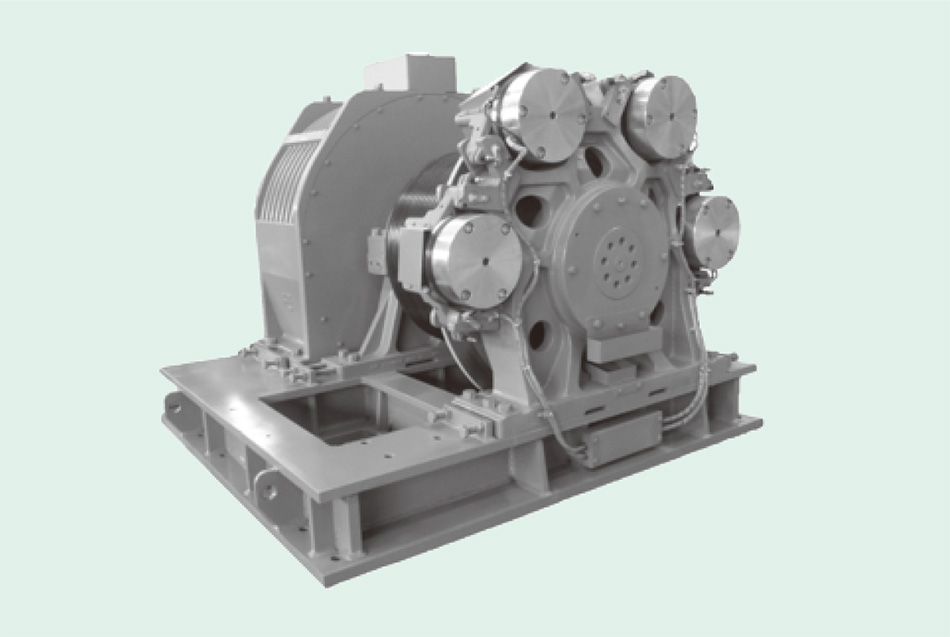

Fig. 3—91-kW Traction Machine.

The compact design has reduced the volume of the traction machine, providing greater flexibility for elevator machine room layout.

The compact design has reduced the volume of the traction machine, providing greater flexibility for elevator machine room layout.

The traction machine in the new product range was upgraded to provide faster speed and higher capacity. It was also made smaller than the previous model to satisfy constraints on the floor area and height of the elevator machine room (space for installing traction machines and control panels) and on securing access for maintenance. Fig. 3 shows a photograph of the highest capacity traction machine in the current models manufactured in China.

Development of the traction machine included making it smaller to fit inside the machine room and making maintenance easier. This smaller size was achieved by adopting a support structure that combines both an inner rotor and shaft and by changing from drum to disk brakes. The diameter of the sheave was also reduced. Along with these changes, the size of the traction machine was also reduced by using welded steel plate for the machine base and making it thinner, and by making the machine beam bearer thinner. This resulted in the traction machine being 465 mm shorter than the previous model, and reduced the required machine room height by 900 mm.

Higher-capacity power modules were adopted for the drive system, and the inverter capacity was increased by developing techniques for operating insulated-gate bipolar transistor (IGBT) modules in parallel, current equalization, and protection. Small heat pipes with high thermal conductivity were adopted to deal with the problem of heat generated by the power modules due to the increased capacity, thereby more than doubling the life of the power modules (relative to the previous model). To prevent interference with external power supplies, a reduced-size inductor-capacitor-inductor (LCL) filter circuit was also included to keep maximum harmonic currents below 25% of the level permitted by the Chinese national standards.

High-speed elevators are also called on to make efficient use of space, with a requirement to shrink the dimensions of the hoistway. To achieve this, Hitachi adopted an emergency terminal speed limiting (ETSL) system. This system satisfies Safety Integrity Level (SIL) 3 in the EN61508:2010 standard for functional safety and works by comparing the actual elevator car speed against the maximum speed from which it can brake to a halt in the space available to determine when an emergency stop is needed. This guarantees that the speed at which the elevator car impacts the buffer at the bottom of the hoistway will be kept below a certain level, even if an emergency occurs. The system allows the buffer to be smaller so that it takes up approximately 30% less space compared with when this system is not used.

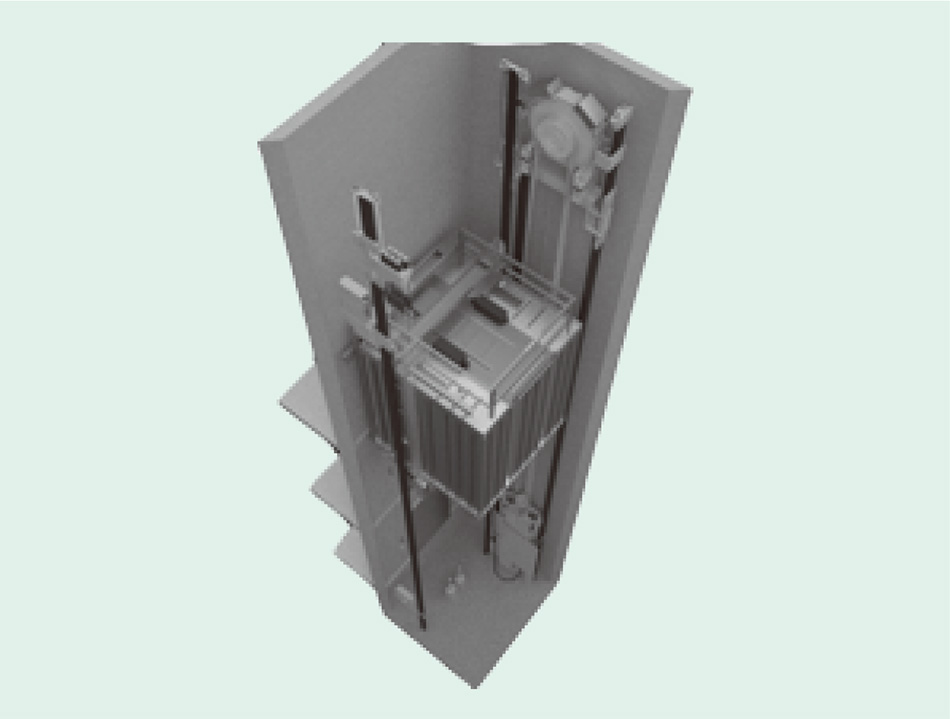

Fig. 4—Machine-room-less Elevator.

The traction machine is installed at the top of the hoistway to make more efficient use of space.

The traction machine is installed at the top of the hoistway to make more efficient use of space.

Hitachi developed its latest machine-room-less elevators amid rapidly growing demand for space-efficient elevators that do not require machine rooms.

Operated by a thin-profile traction machine at the top of the hoistway, this elevator was designed for greater safety and reliability and more efficient use of space for the same elevator specifications, while also satisfying market demands for comfort and high speed.

The structure of the traction machine was optimized to make it thinner, and the elevator reduces the load on the building by having the traction machine attached to the top of the rails and relocating the components in the hoistway to save a considerable amount of space (see Fig. 4).

The influence of traction machine vibration has been reduced by using high-performance vibration-isolating materials to improve ride comfort. The safety and reliability of the elevator have been improved further by adopting seismic design practices and making various improvements, including to the traction machine braking torque and to the level of protection and insulation.

Fig. 5—Destination Floor Reservation System.

Along with controlling the flow of people, the system provides efficient operation by enabling elevators to stop at fewer floors.

Along with controlling the flow of people, the system provides efficient operation by enabling elevators to stop at fewer floors.

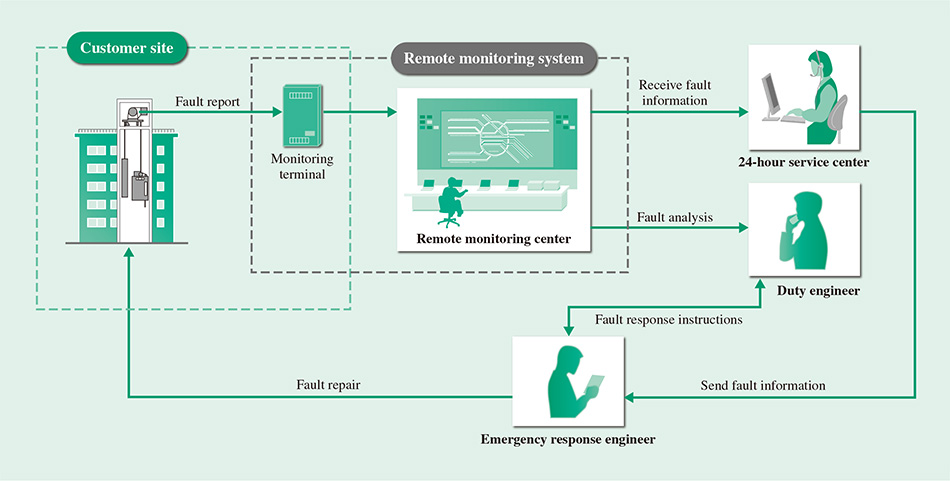

Fig. 6—Elevator Service Support System.

The system uses information technology to provide remote support to maintenance staff.

The system uses information technology to provide remote support to maintenance staff.

The following technologies have been incorporated into the models manufactured in China to improve their energy efficiency. They have acquired Class A energy efficiency certification under the VDI 4707 and ISO 25745 standards, and also help qualify buildings for Leadership in Energy and Environmental Design (LEED) certification, a voluntary certification system administered by the U. S. Green Building Council.

Along with the passenger elevators described above, viewing elevators, hospital elevators, and firefighting elevators are also being added to the models manufactured in China. Featuring greater use of advanced technology and concern for protecting the environment, these Chinese-made elevators are safe and comfortable to ride in and are competitive in the Chinese market. They have won awards from the Chinese government and China Elevator Association as well as a science and technology encouragement prize from the Guangdong Mechanical Engineering Society (awarded to the high-speed elevator in 2015).

The elevators have performed well in the Chinese market with sales growing annually since the initial product launch in 2010, and the models manufactured in China have become Hitachi's flagship elevator models in China accounting for more than 50% of orders by volume in 2015.