1. Technological Trends in Advanced Devices and Diversity of Customer Requirements

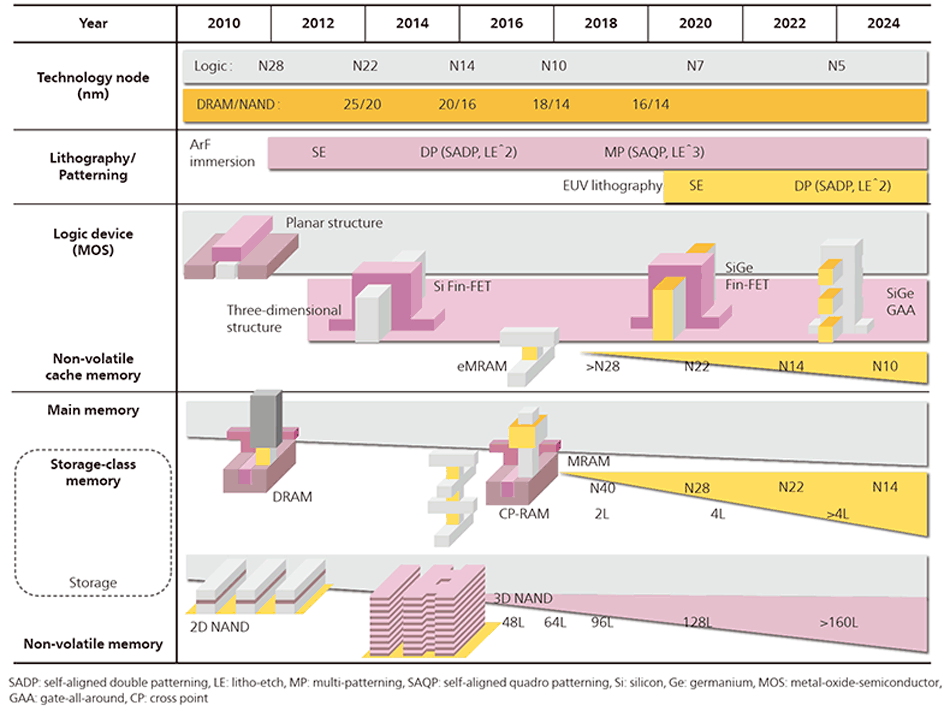

Progress in end products such as smartphones, servers, automobiles and robots is driven by improvements in the performance of semiconductor devices. These improvements have been achieved not only through miniaturization but also by the introduction of three-dimensional structures and new types of memory.

The current device generation will shift to 7 nm and less, thanks to the adoption of multiple patterning technology and extreme ultraviolet (EUV) lithography. On the other hand, production volumes of 3D-NAND flash memory that vertically stacks memory cells are increasing and the number of stacks is expected to reach 100 layers in a few years. A number of new materials such as SiGe (silicon germanium) are being examined for the channel material of the fin-shaped field effect transistor, which is used in high-performance logic processors. In the case of new memory, magnetoresistive random access memory (MRAM) has moved a step ahead of other types of memory with its high access speed, data retention and endurance. MRAM is set to shift from the development stage to the mass production stage.

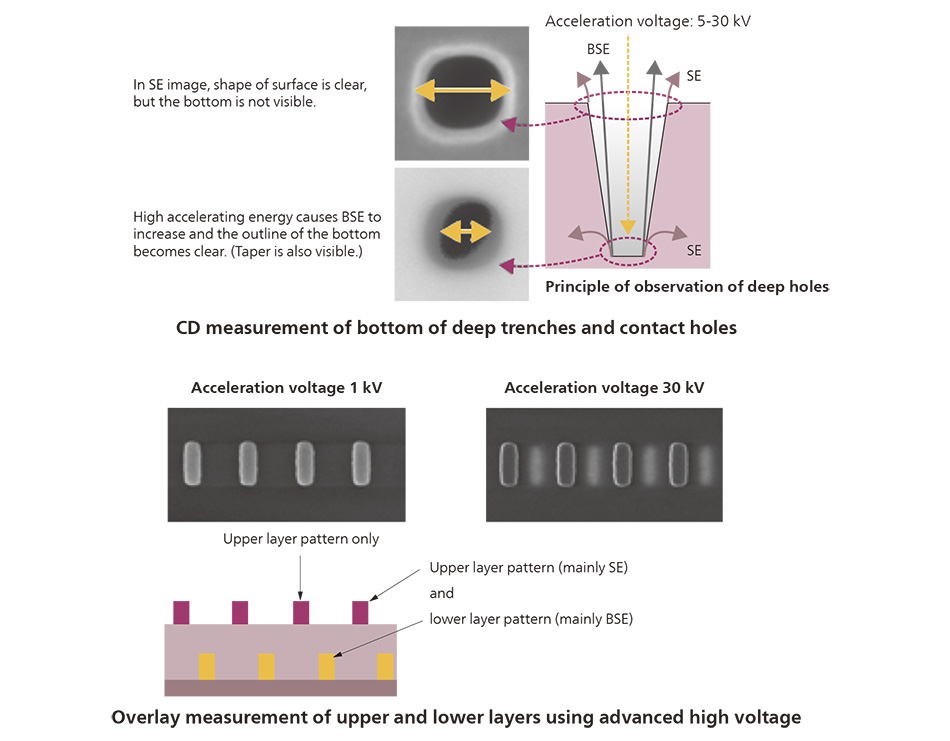

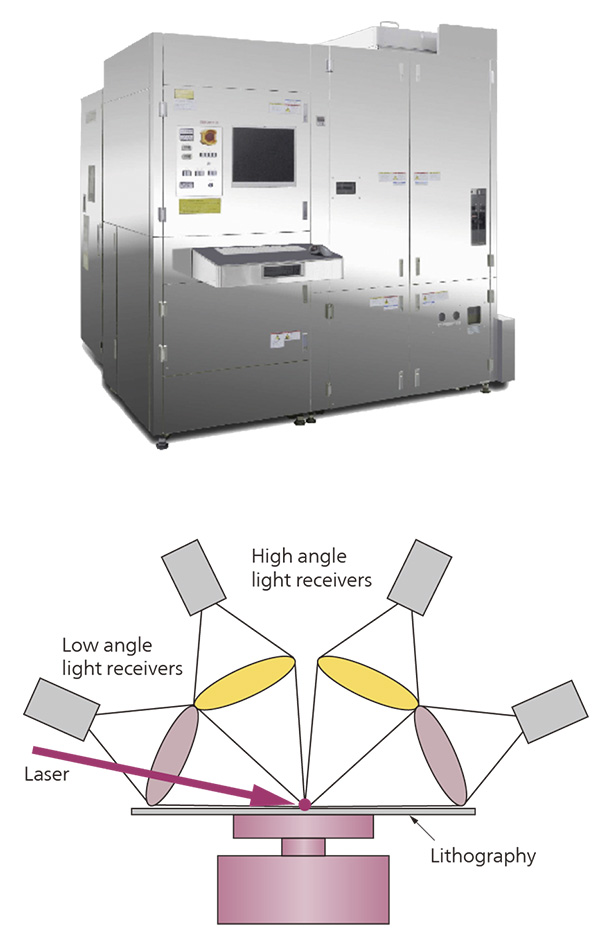

Customer needs are also changing in response to these technological trends. In addition to existing technologies, control of critical particles/defects in the EUV lithography process, high-precision processing and metrology for MRAM and new materials are required. Technologies for etching and critical dimension measurement for deep trenches and holes are also important in 3D-NAND memory manufacturing.

Hitachi Group continues to provide advanced technologies and solutions that satisfy these diversified customer needs.

(Hitachi High Technologies Corporation)