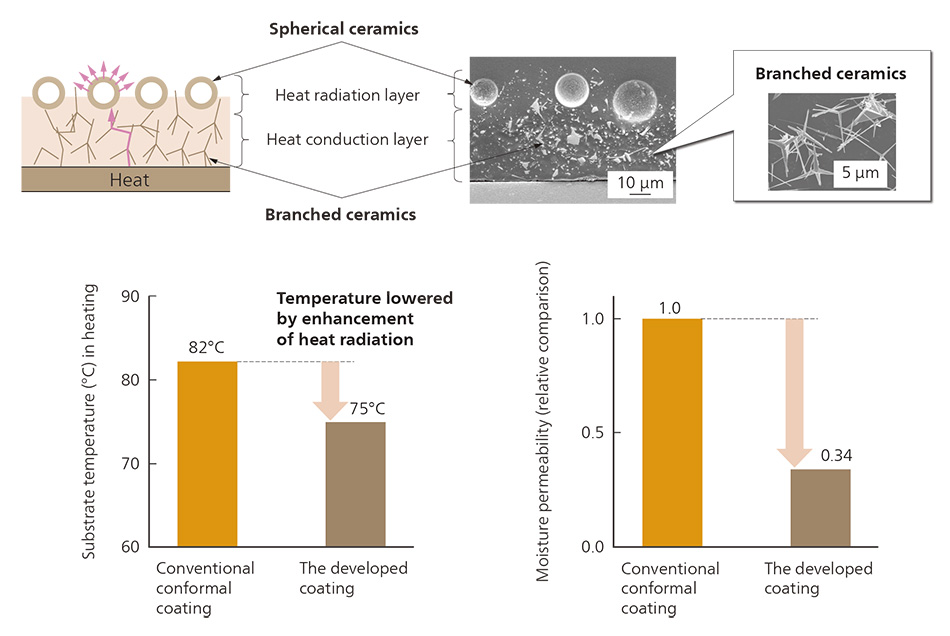

1. Circuit Board Coating with Excellent Heat Radiation and Reliability

Conformal coating is usually applied to the surfaces of circuit boards for home electric appliances, mobile devices and other electronic equipment to prevent short circuits caused by dew condensation on the boards. Meanwhile, circuit boards are required to exhibit a high level of heat dissipation characteristics because heat generation density increases due to downsized circuits and integrated electronic components. Therefore, Hitachi has developed a novel conformal coating with excellent heat radiation.

A resin with low moisture permeability is used as a main component to secure greater reliability. Higher heat dissipation is achieved than those of conventional heat radiation materials. Branched ceramics distributed in the heat conduction layer increase heat transfer channels between the particles and achieve high heat conductivity. On the surface, spherical ceramics with a high radiation rate are exposed to increase the radiation area and improve the heat radiation.

In this coating material applied to a circuit board, spherical ceramics with low specific gravity come to the surface and simultaneously form a two-layer structure. Therefore this new coating allows use of the conventional process of applying coating materials without change. This coating is expected to be applied to devices for which a high level of heat radiation and moisture resistance are required.

1. Cross-sectional view of the newly developed coating (top) and heat radiation property and moisture permeability of the coating (bottom)