Technological Innovations Accelerating Worldwide Digitalization

A growing number of companies have recently started implementing IoT solutions that use various types of data and new technologies such as artificial intelligence to increase the efficiency of business operations and provide new value. Linking existing systems to cutting-edge technologies is a key requirement for IoT solutions, and the continually evolving nature of these technologies has created a variety of development issues. Hitachi has responded by providing Lumada platform services that simplify the development of IoT solutions. This article provides a general description of the latest technologies in use today, along with the issues facing IoT solution development and the main components of the Lumada platform services used to solve them—Lumada Solution Hub and Hitachi digital-twin solution for manufacturing.

Industrial AI Laboratory, Research & Development Division, Hitachi America, Ltd. Current work and research: Research and development of IoT platforms.

Connectivity Research Department, Center for Technology Innovation – Electronics, Research & Development Group, Hitachi, Ltd. Current work and research: Research and Development of Hitachi digital-twin solution for manufacturing.

Research & Development Group, Hitachi, Ltd. Current work and research: Research on open source software and IoT platforms. Society memberships: The Information Processing Society of Japan (IPSJ), the Institute of Electronics, Information and Communication Engineers (IEICE), and IEEE Computer Society.

Service Platform Business Division Group, Services & Platforms Business Unit, Hitachi, Ltd. Current work and research: Development of cloud services and Lumada platform services. Society memberships: IPSJ.

Application Cloud Services Business Division, Service Platform Business Division Group, Services & Platforms Business Unit, Hitachi, Ltd. Current work and research: Development of Hitachi digital-twin solution for manufacturing.

With the dramatic rise of digital technologies, the world is entering the Internet of Things (IoT) era, which has made it possible to create new value by connecting a wide range of devices to the Internet. The rise of digital technologies has also generated a variety of innovations, forcing companies to keep up with the business environment's accelerating pace of change to increase their competitiveness or dominance in the market. In response, a growing number of companies are innovating their business operations by using the latest artificial intelligence (AI) technology to analyze data gathered from various devices and systems to provide transparency and feedback to those operations. The scope of the innovation is also increasing from individual departments to entire value chains encompassing multiple companies.

This article provides a technical overview of the Lumada platform services that are helping companies digitalize their business operations.

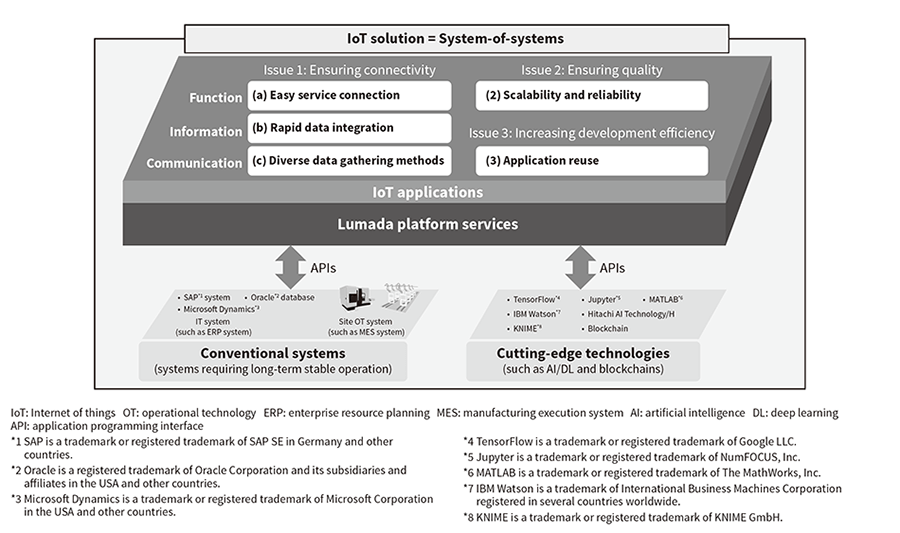

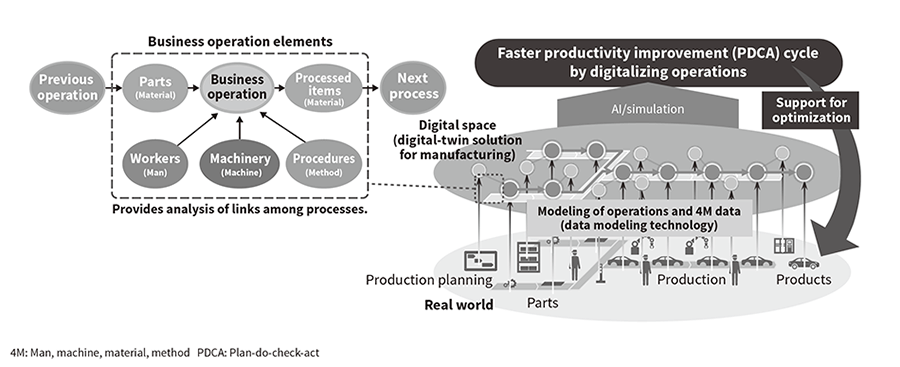

IoT solutions improve business operations by gathering data from existing enterprise resource planning (ERP) systems and manufacturing execution systems (MES), and using cutting-edge technologies such as AI and deep learning (DL) to uncover new value (see Figure 1). As they promote business reforms, these IoT solutions need to rapidly update systems in response to changes in the items being improved.

Each of the solutions can be regarded as a system-of-systems(1) that creates a larger system by connecting multiple systems and generates new value. Developing this sort of system can increase the number of devices to connect and create unplanned changes, resulting in the technical issues below.

Figure 1—IoT Solutions in the Form of System-of-Systems, and Functions Provided by Lumada Platform Services IoT solutions are systems that combine existing systems with cutting-edge technologies, and have system-of-systems characteristics.

IoT solutions are systems that combine existing systems with cutting-edge technologies, and have system-of-systems characteristics.

Lumada platform services provide solutions to the issues encountered during IoT solution development. The solutions are provided in the form of platform functions. Table 1 shows the functions provided for handling each of the issues above.

Overviews of two of these functions follow below. Section 3 covers Lumada Solution Hub, a product addressing Issue 3, and Section 4 covers Hitachi digital-twin solution for manufacturing, a technology addressing Issue 1 (b).

Table 1—Functions Provided by Lumada Platform Services and Corresponding Products/Technologies Lumada platform services provide functions that address a number of issues encountered during IoT solution development.

Lumada platform services provide functions that address a number of issues encountered during IoT solution development.

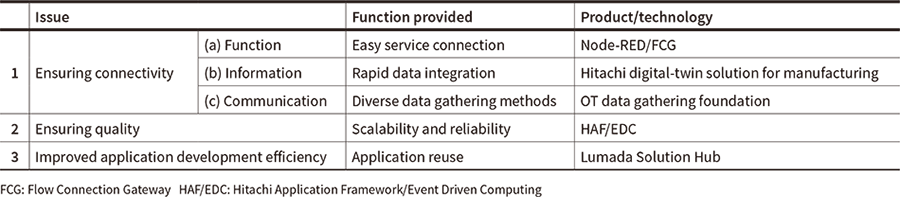

Among the functions provided by Lumada platform services (described in Section 2), Lumada Solution Hub is a product for solving Issue 3, application reuse. Lumada Solution Hub prioritizes interconnectability with other platforms, and is built using industry-standard open-source software (OSS). Its main features are:

Figure 2 shows the architecture used to achieve the features of Lumada Solution Hub described in the previous subsection. Lumada Solution Hub is composed of three main layers. An overview of the technologies and OSS used in each layer is given below.

Figure 2—Lumada Solution Hub Architecture Lumada Solution Hub is composed of a cloud platform and packaged solutions. The cloud platform is composed of IaaS and a management platform. The packaged solutions include an application development environment building solution and business operation solutions for different industries.

Lumada Solution Hub is composed of a cloud platform and packaged solutions. The cloud platform is composed of IaaS and a management platform. The packaged solutions include an application development environment building solution and business operation solutions for different industries.

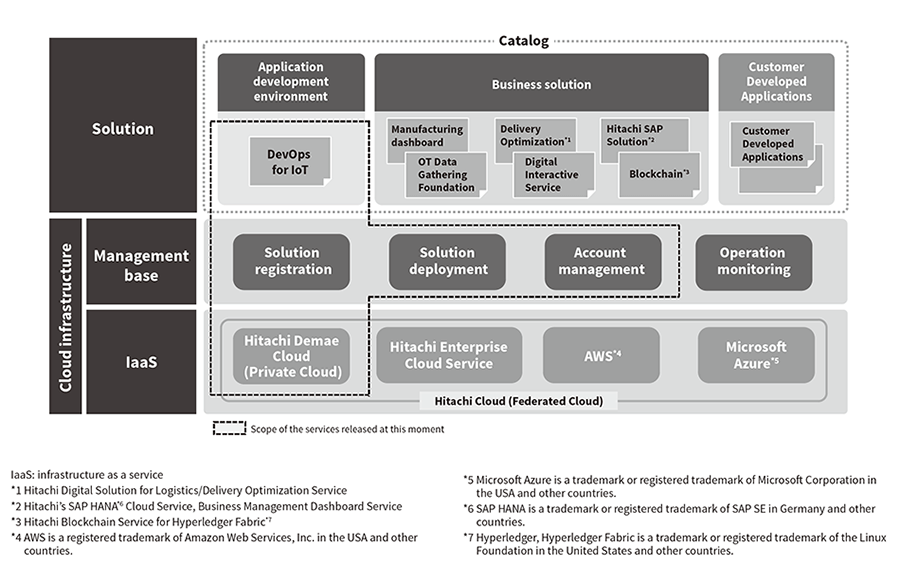

Work in industries such as the logistics, construction, and manufacturing takes shape by executing business operations segregated by function in a predetermined sequence, and repeatedly passing along the results of each operation to the next operation. This is the way that goods are transported (logistics industry), buildings are built (construction industry), and products are manufactured (manufacturing industry). The business operations performed to carry out these work activities are being made more efficient by digitalization, but diversifying market needs are creating demand for further efficiency gains.

A key requirement for creating these efficiency gains is to move away from focusing only on increasing the efficiency of individual operations, and instead to optimize the flow of business operations over the entire value chain by considering the connections among the wide range of operations that make up work activities.

But optimizing the entire flow of business operations requires a method that enables the compilation and integrated management of massive volumes of heterogeneous data generated by each business operation system.

The manufacturing industry is often characterized by production operations such as pressing, painting, and assembly that are connected in the form of production lines, while individual production operation systems are optimized to their respective production operations and built as different systems.

Hitachi has responded by examining manufacturing industry issues resembling those described above, and developing Hitachi digital-twin solution for manufacturing. Digital-twin solution brings together a wide range of different site data scattered throughout a plant's business operations to reproduce entire production lines in a digital space. It provides a simulation space that models the real world to help visualize and analyze physical-world events related to the plant, products, and other issues. Besides plant-owning manufacturers, it can also be used to assist companies in other industries that have standardized business operation flows resembling production lines.

Digital-twin solution makes it easy to bring together and maintain operational technology (OT) and IT data stored separately by various business operations. It is a data usage platform that uses AI analysis and simulations to assist ongoing productivity improvement (see Figure 3), and uses the connections of production operations to model site data. Specifically, it defines production operations and elements related to production operations (such as people, equipment, materials, and operating procedure manuals) as 4M*5 data, and uses an original data model that reproduces the connections among the previous and the next production operations on the basis of the processed items created by the production operations (the ‘material' element of 4M data).

Digital-twin solution can register the modeled site data in a graph database and extract site data for the production operations of each finished product. These features can create transparency by associating each finished product with the applicable production operations, equipment used, and processes performed. Digital-twin solution makes it easy to extract and integrate the required data whenever needed, without expert knowledge of production operations, helping shorten the plan-do-check-act (PDCA) cycle for data analysis.

Figure 3—Overview of Digital-twin Solution for Manufacturing Hitachi digital-twin solution for manufacturing models site data and stores it in a graph database by using the relationships between business operations and process elements including people, equipment, materials, methods, and procedures.

Hitachi digital-twin solution for manufacturing models site data and stores it in a graph database by using the relationships between business operations and process elements including people, equipment, materials, methods, and procedures.

This article has provided an overview of the Lumada platform services used to simplify the work of IoT solution development, along with a general description of the development background and technologies of two of its component products/technologies—Lumada Solution Hub and Hitachi digital-twin solution for manufacturing.

The use of data to digitalize and improve the efficiency of business operations and systems will continue gaining prominence in the years ahead, and platforms for assisting this work will play an increasingly important role.

Hitachi plans to continue developing technologies for simulating digitalized business operations and for simply and securely operating today's increasingly complex software, and applying them to Lumada platform services.