Water Environment Solutions that Facilitate Ongoing Use of Water Resources

Monitoring and control systems play a vital role in the routine operational management of water and sewerage infrastructure. Meanwhile, recent years have seen rising demand for monitoring and control to be augmented by additional functions that provide a platform for the use of collected data to make ongoing operational improvements. In response, Hitachi has developed systems that combine monitoring and control with a data analysis platform and has established practices for utilizing the real-time data archived in monitoring and control systems. Furthermore, because the water supply and sewerage industries require that system upgrades be undertaken without interrupting monitoring and control, Hitachi has also developed a process input/output switching interface that enables seamless switch-over between the old and new systems. By ensuring the organic interoperation of monitoring and control with equipment management systems, this also provides support for the plan-do-check-act cycle, including maintenance, through the utilization of information from equipment journals and maintenance work as well as monitoring and control data.

The December 2018 revisions to Japan’s Water Supply Act made operational management a key policy focus by redefining the purpose of the law, as specified in its initial section, from the plentiful supply of clean low-cost water achieved through the well-planned provision of water supplies and the protection and enhancement of the water industry to the plentiful supply of clean low-cost water achieved through the strengthening of water infrastructure(1). In the case of sewerage, the Strategy for Accelerating New Sewerage Vision published in 2017 identified the optimization of wastewater treatment systems as the third of its high-priority items. Progress is also being made on regional consolidation and coordination as a means of improving operational management(2).

Given this background, monitoring and control systems not only play a vital role in routine equipment operation and operational management, there is also an expectation that the data they collect during this routine operation will be used in the plan-do-check-act (PDCA) cycle of improvement activities.

To satisfy these expectations, Hitachi has developed techniques for using monitoring and control systems as edge computing systems for operational management and for the use of data in improvement activities. This article explains how this works and also describes the functions for supporting operational management that are available in Hitachi’s monitoring and control system.

Meanwhile, along with the increasing number of monitoring and control systems that are being upgraded, there is also rising demand from the water supply and sewerage industries for system upgrades to be undertaken without interrupting monitoring and control operation. The article also describes a process input/output (PI/O) switching interface that Hitachi developed for this purpose.

Along with operational data from monitoring and control systems, data from equipment journals and maintenance work has an important part to play in the PDCA cycle for making improvements to operational management. The article also describes an equipment management system for utilizing this data.

Along with being edge computing devices that make use of data in routine operational management, monitoring and control systems can also be connected to an Internet of Things (IoT) platform to provide an environment in which the collected data can be put to use.

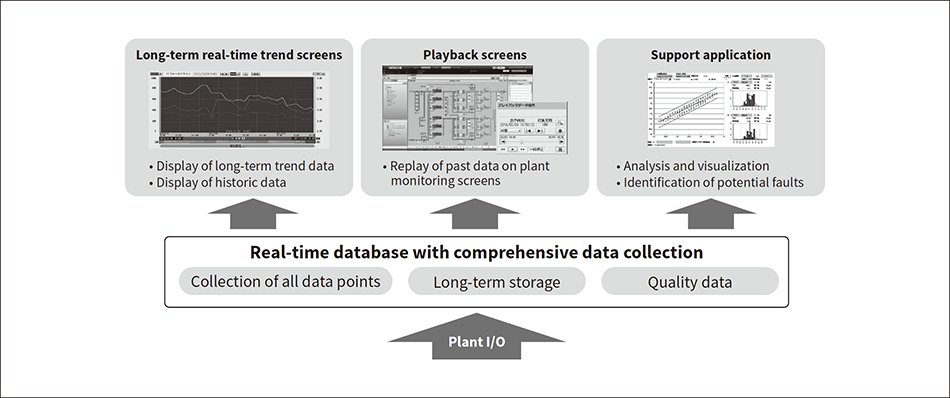

Figure 1 — Real-time Database with Comprehensive Data Collection By providing long-term storage of all data points along with quality data, the database enables the data to be used in a variety of ways via the screens.

By providing long-term storage of all data points along with quality data, the database enables the data to be used in a variety of ways via the screens.

The arrival of the IoT means that the real-time data routinely collected by monitoring and control systems can also be put to use to uncover new knowledge.

In the past, real-time data in Hitachi’s monitoring and control system was used to keep track of equipment status by displaying trend graphs of data collected at one-second intervals, although the real-time database only had the capacity to store about one day’s worth of data. Moreover, the limited hard disk capacity of monitoring and control systems also limited the number of I/O points for which data could be stored. As storing all equipment data was not feasible, data was only collected for designated I/O points. This meant that data that had not been designated for storage would not be available if subsequently needed for analysis.

To overcome these constraints on the use of data, Hitachi has taken advantage of data compression and recent improvements in the storage capacity of monitoring and control systems to develop a real-time database system that is able to collect all data input points at one-second intervals. The database has been designed such that collection intervals and storage times can be easily modified to suit different system sizes and equipment operation. While storing a month of data collected at one-second intervals or six months of data collected at 10-second intervals are the default options, the system can also be configured to save 10 years of data at one-second intervals, for example.

As well as measurements, the database can store quality information such as upper or lower limits and abnormal rates of change, and it can also be used to replicate past operating conditions or for cleansing data in preparation for analysis. Example uses in plant operation include: (1) Use of the long-term real-time trending function to provide information for comparison by displaying similar operational data from the past alongside current data, (2) Use of the playback function (described below) to replicate non-standard or abnormal situations, and using this as a basis for making improvements or identifying new knowledge, and (3) Use of online data analysis for tuning control model parameters (see Figure 1).

The ongoing regional consolidation and coordination in the water supply and sewerage industries has opened up possibilities for using data in more sophisticated ways by combining data from different sites or data obtained during maintenance. Monitoring and control are done by self-contained systems equipped with functions for routine tasks that range from the monitoring and operation of equipment to the preparation of records. As a result, the data collected by these systems tended only to be used within those same systems. While the ability to export data for use in other systems via formats such as comma-separated value (CSV) did exist, because the data was limited to column titles and tabulated values, it was difficult for anyone other than system personnel to find and use the data they needed. What was needed to make equipment operation data available to the many other departments at water supply and sewerage utilities was an easy way for them to find and extract data. Moreover, the different data formats used by different systems needed to be aligned before the combined data could be used.

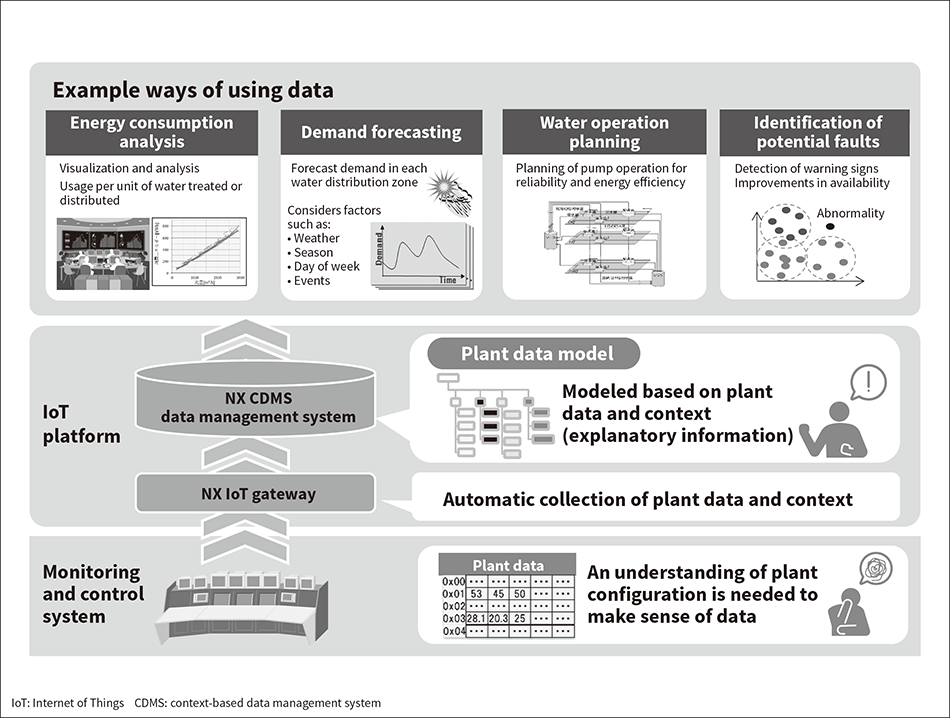

To overcome these problems, Hitachi has developed an IoT platform for data analysis(3) (see Figure 2). The platform uses NX IoT gateway for monitoring and control system data collection and the NX Context-based Data Management System (CDMS) for data management. The main functions are as follows.

The IoT platform assigns meaning and interrelationships to the plant data held by monitoring and control systems and allows users to acquire the data they need in a consistent format in accordance with the structure of the plant data model by tracing the equipment or machinery of the plant data model.

Note that once a plant data model is defined, it can be used at other sites that use the same equipment. This standardization of plant data models provides unified ways of accessing and using data within individual utilities or across a number of different utilities.

Examples of how data could be used in the water industry include: (1) Determining information on usage per unit of water treated or distributed based on energy consumption analysis, and using this to identify more efficient ways of operating, (2) Generating demand forecasts or water supply plans that encompass a number of different facilities, or (3) Identification of potential faults by combining real-time data from monitoring and control systems with data obtained during on-site inspections.

Rather than needing to be an on-premises system located at the utility itself, the IoT platform can be made available via the cloud, making it possible to use data in conjunction with cloud-based open data sources and analysis tools.

Figure 2 — IoT Platform for Data Analysis The IoT platform facilitates data analysis and supports more advanced maintenance practices by assigning meaning and interrelationships to the diverse and complex plant data acquired from monitoring and control systems.

The IoT platform facilitates data analysis and supports more advanced maintenance practices by assigning meaning and interrelationships to the diverse and complex plant data acquired from monitoring and control systems.

Hitachi is continuing to add new functions for the operational management of water and sewerage to its monitoring and control system. This section describes those functions that support regional consolidation and skills transfer.

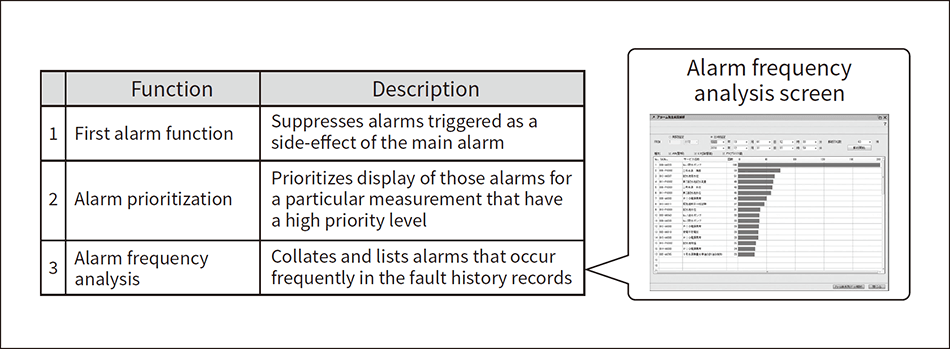

Figure 3 — Key Alarm Management Functions that Comply with EEMUA 191 A first alarm function, alarm prioritization function, and function for analyzing alarm activity and frequency are provided to help operators respond to alarms.

A first alarm function, alarm prioritization function, and function for analyzing alarm activity and frequency are provided to help operators respond to alarms.

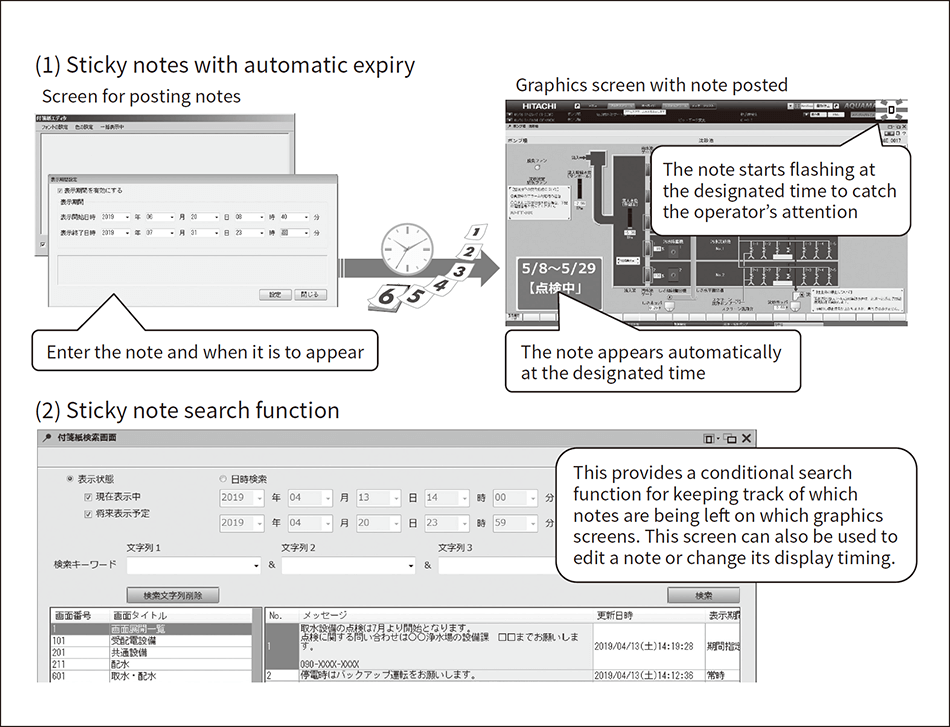

Figure 4 — Sticky Note Function This includes an expiry function that allows the start and end display times to be specified when a note is posted. The note is automatically displayed during the specified time period only. A sticky note search function is also available to show which notes are being left on which graphics screens.

This includes an expiry function that allows the start and end display times to be specified when a note is posted. The note is automatically displayed during the specified time period only. A sticky note search function is also available to show which notes are being left on which graphics screens.

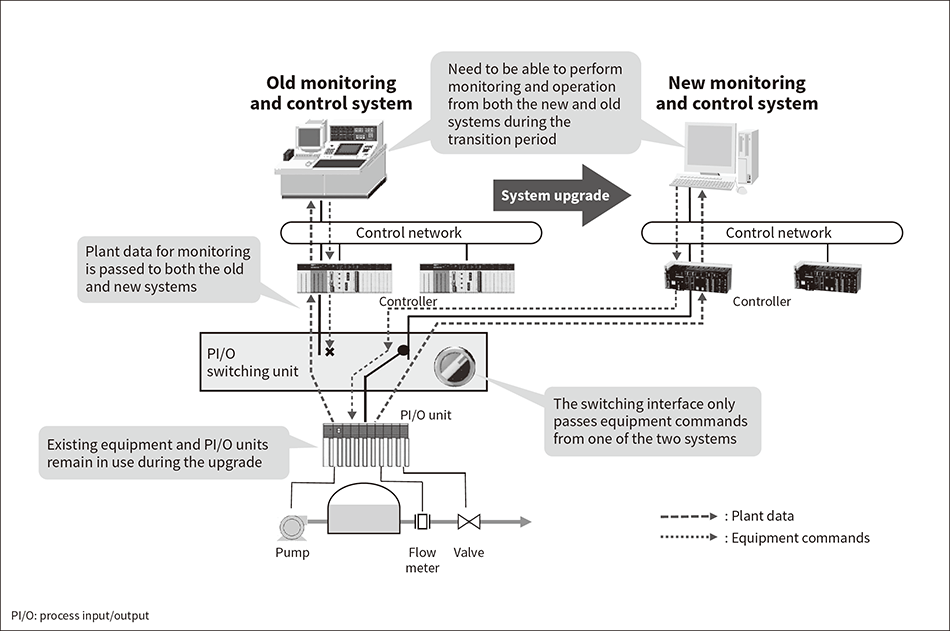

Water supply and sewerage facilities operate continuously 24×7, 365 days-a-year. This means that switching over to a new system when upgrading a monitoring and control system must be done without interrupting its operation. Moreover, because the timeframes for upgrading mechanical and electrical equipment are different, it is not uncommon for an upgrade to involve electrical equipment only. The requirement in such cases is often to leave the PI/O units that interface directly with mechanical equipment in place when performing the monitoring and control system upgrade. When PI/O units are left unchanged, the inputs and outputs to these units remain the same as before the upgrade. To keep monitoring and control functions operating under this constraint, past practices for achieving a seamless transition have included: (1) Undertaking the transition over a number of days, performing equipment installation and testing of the new system during the daytime and reverting to the old system each night, or (2) Monitoring the operation of the old and new systems in parallel, with temporary measures being put in place for using the existing hard-wired circuits and software logic. The difficulty with these methods is that they take a lot of preparatory investigation and work to set up. To overcome this problem, Hitachi developed a PI/O switching interface that eliminates this complex preparatory work prior to monitoring and control systems upgrades.

In the example shown in Figure 5, the monitoring and control system is being upgraded with the existing infrastructure from the equipment (pumps, valves, flow meters, and so on) to the PI/O units being left in place and the new PI/O switching interface connected between the controller and PI/O unit. By passing plant data (status information) to both the old and new monitoring and control systems, this configuration enables the old and new systems to continue plant monitoring in parallel without requiring any temporary measures. The PI/O switching interface also has a switch that determines whether equipment commands from the old or the new system are passed to the plant. Because equipment commands from the other system are ignored, there is no risk of misoperation. This approach means that operators can continue to use the old system to view plant operation while commissioning of the new system is in progress during the day, and then use the switching function to change back to operating the plant using the old system during the night when commissioning work is on hold.

Figure 5 — Use of PI/O Switching Interface when Upgrading Monitoring and Control System The example shows the transition period during an upgrade of a monitoring and control system when existing infrastructure is still being used between the equipment (pumps, valves, flow meters, and so on) and the PI/O units. Use of the PI/O switching interface during this time allows plant monitoring to continue on both the old and new systems. Similarly, the interface only passes commands back to the equipment from one of the two systems.

The example shows the transition period during an upgrade of a monitoring and control system when existing infrastructure is still being used between the equipment (pumps, valves, flow meters, and so on) and the PI/O units. Use of the PI/O switching interface during this time allows plant monitoring to continue on both the old and new systems. Similarly, the interface only passes commands back to the equipment from one of the two systems.

Dealing with aging plant is an issue for Japan as water infrastructure installed during the era of rapid growth comes due for replacement. The revisions to the Water Supply Act identified appropriate asset management as a means of strengthening the infrastructure of water utilities, with utilities being urged to adopt the following four measures(1).

Hitachi offers equipment management systems as a solution for supporting sustainable water supplies.

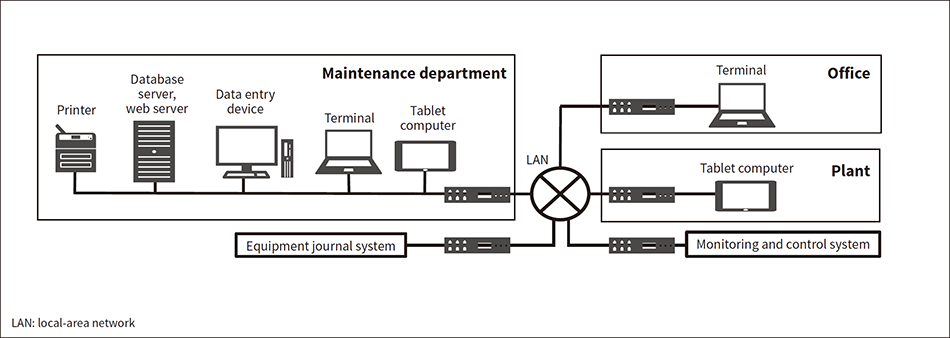

An equipment management system manages water infrastructure records (records of work done, equipment journals, repair history, and as-built drawings and documentation) as well as information on inspections, repairs, accident and fault response, and other work associated with maintaining and restoring water infrastructure (see Figure 6). This management information provides a basis for planning equipment upgrades and financial management.

The features of the equipment management system are as follows.

These functions contribute to the sustainability of water supplies by enabling the appropriate management and more efficient maintenance of water infrastructure.

Figure 6 — Example Configuration of Equipment Management System The system manages information on inspections, repairs, accident and fault response, and other work associated with maintaining and restoring water infrastructure. It also manages water infrastructure records (records of work done, equipment journals, repair history, and as-built drawings and documentation).

The system manages information on inspections, repairs, accident and fault response, and other work associated with maintaining and restoring water infrastructure. It also manages water infrastructure records (records of work done, equipment journals, repair history, and as-built drawings and documentation).

The equipment management system can further improve the efficiency of maintenance work by incorporating the operational records of equipment through integration with the Hitachi’s monitoring and control system. This supports condition-based maintenance (CBM) whereby equipment operating hours and fault information are used as a basis for scheduling maintenance and upgrades by importing this data for important items of equipment and cross-referencing it with the water infrastructure records.

This article has described the infrastructure for utilizing data from the monitoring and control systems of water and sewerage systems that are at the maintenance phase of their lifecycle as well as new functions and an equipment management system. Along with routine operation and maintenance, these systems also provide a basis for utilizing the data they collect in this role for ongoing operational improvements. Information and communication technologies (ICT) are essential to the water and sewerage industries given the public expectations for ongoing contributions to the safety and reliability of water. Accordingly, monitoring and control and equipment management systems are recognized as having a vital role to play as edge computing components that incorporate operational technology (OT). Through its monitoring and control and equipment management systems that combine IT, OT, and products, Hitachi intends to continue contributing to sustainable water and sewerage infrastructure.