Heavy Haul Freight Transportation System: AutoHaulAutonomous Heavy Haul Freight Train Achieved in Australia

Highlight

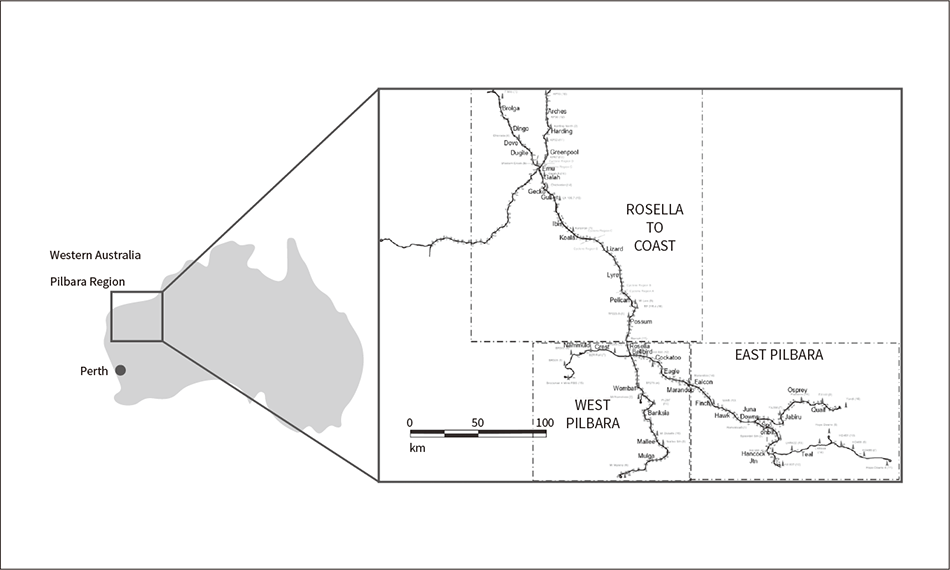

There are many iron ore rail lines in the Pilbara region, located in North-West Australia. Global mining company Rio Tinto Limited operates a fleet of heavy haul iron ore trains 24 hours a day from its 16 mines to four port terminals overlooking the Indian Ocean. To increase their operational capacity and reduce transportation time, Rio Tinto realized that driverless (GoA4) operation of its trains was the way to achieve this. The company established a framework agreement with Hitachi Rail STS S.p.A. This project was named AutoHaul, and two companies worked closely on its development over several years. Since completing the first loaded run in July 2018, these trains have now safely travelled more than 11 million km autonomously. The network is the world’s first driverless heavy haul long distance train operation.

Introduction

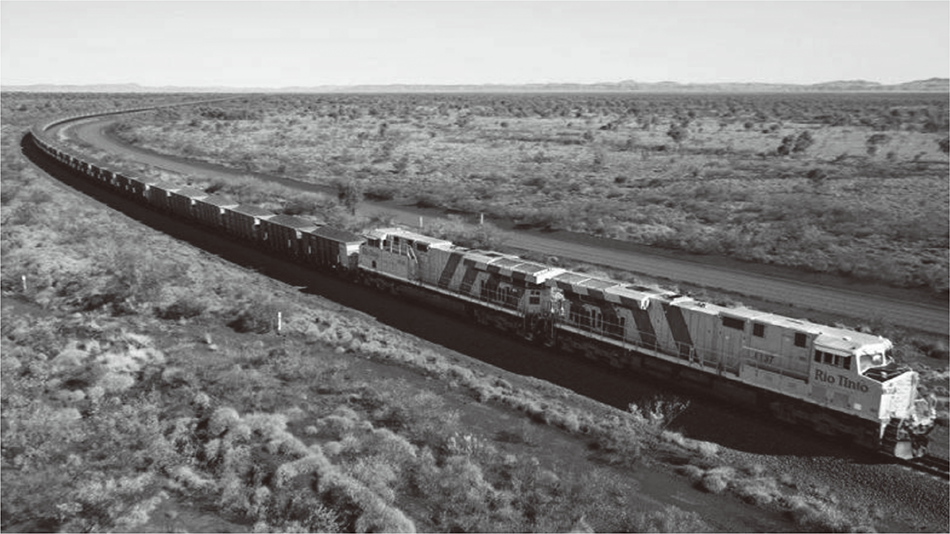

Rio Tinto Limited, a leading global mining group, operates an autonomous fleet of 221 heavy haul locomotives along its 1,700 km line 24 hours a day extracting iron ore from mines in the South and transporting it across the remote Pilbara region to ports 300 km away overlooking the Indian Ocean. A typical train formation includes a triple-headed diesel electric locomotive and 240 wagons loaded with 106 t each car. Typical train length is 2.5 km and total weight is 28,000 t.

Maximizing transportation efficiency is the first priority of train operations and trains can depart after loading has completed without a pre-scheduled train operation diagram. Complete train operation is monitored remotely by a team of train controllers and maintainers from Rio Tinto’s Operations Center in Perth more than 1,500 km away (see Figure 1 and Figure 2). The operation of this autonomous train is achieved by the heavy haul freight transportation system, AutoHaul*1, developed through co-creation between Rio Tinto and Hitachi Rail STS S.p.A. (formerly Ansaldo STS S.p.A.). This article presents the development history and features of AutoHaul.

- *1

- AutoHaul is a registered trademark of Rio Tinto Limited.

Development of AutoHaul

The demand for iron ore has increased year by year and to keep up with the demand Rio Tinto achieved driverless autonomous heavy vehicle (AHV) operation and planned to realize driverless (grades of automation 4: GoA4) operation of iron ore trains. This project, named AutoHaul, is aimed at unlocking significant safety and productivity gains for Rio Tinto, as well as optimizing the company’s iron ore mining system by providing more flexibility and reducing bottlenecks. AutoHaul, the heavy haul freight transportation system, developed in collaborative creation (co-creation) between Rio Tinto and Hitachi Rail STS S.p.A., was granted accreditation by Australia’s Office of the National Rail Safety Regulator on 16 May 2018. Following this, an autonomous train, consisting of three locomotives and carrying around 28,000 t of iron ore, travelled over 280 km from Rio Tinto’s mining operations in Tom Price to the port of Cape Lambert on 10 July 2018. Since this initial run, driverless (GoA4) operation was ramped up in stages and AutoHaul full deployment was achieved in December 2018. Rio Tinto currently runs 98 percent of their AutoHaul equipped locomotive fleet in autonomous mode covering in excess of 11 million km on their network.

Structure of AutoHaul

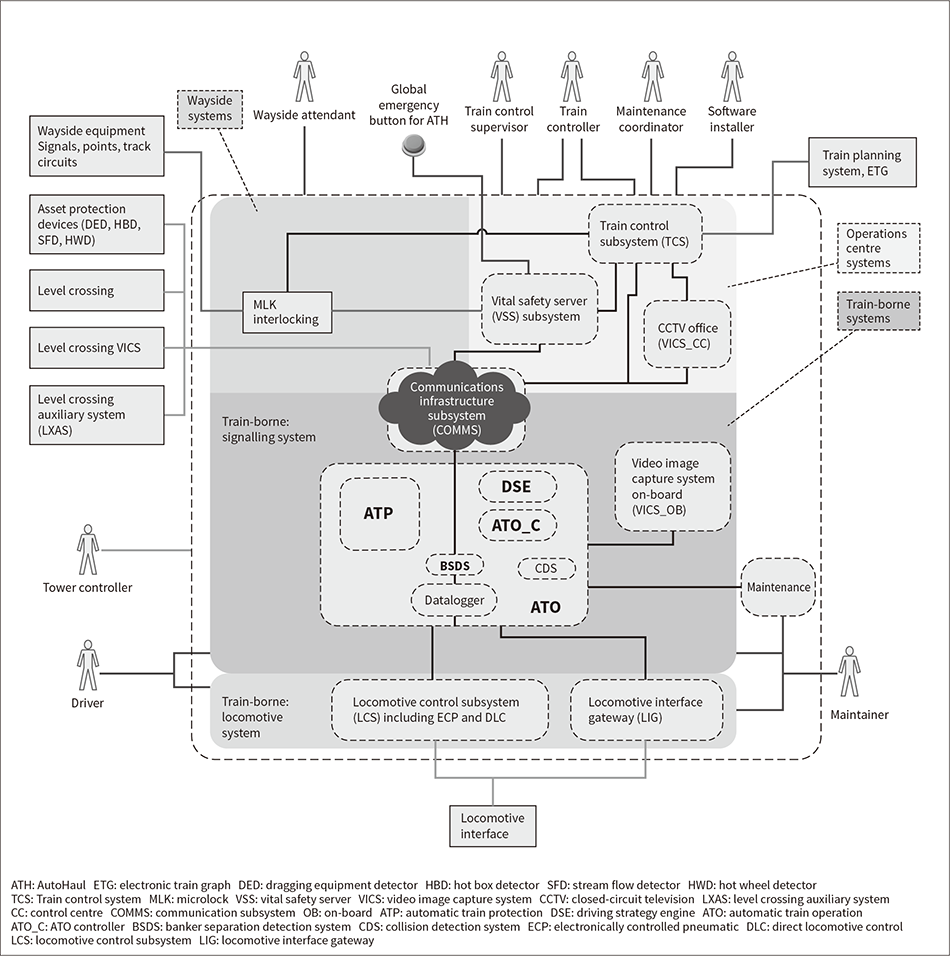

AutoHaul is based on automatic train operation (ATO) and European Train Control System (ETCS) level 2. The system can be broken down into four main segments: communications infrastructure segment, operations center segment, train-borne segment, and signalling and asset protection segment (see Figure 3).

Fig. 3—System Structure of AutoHaul

This figure shows the system architecture of AutoHaul and segments categorized into operation centre, train-borne, communications, signalling, and asset protection.

This figure shows the system architecture of AutoHaul and segments categorized into operation centre, train-borne, communications, signalling, and asset protection.

Level Crossing Protection

Although the train runs through the remote Australian bushland there are some active level crossings along the railway line that intersect with major highways or public roads. There are 42 active crossings on the Rio Tinto network which are protected by the level crossing auxiliary system, This can be broken down into three components.

- Obstruction detection system

Laser based system detects objects within level crossing boundaries. - Closed-circuit television (CCTV)

Provides surveillance coverage of level crossing and record footage via digital video recorder. Manual and automated retrieval/viewing by authorized Operations Center personnel. - Streetlighting

Provides consistent lighting for level crossing. Turns on each time the crossing operates, is obstructed, or when staff view the live feed from CCTV.

Remote Locomotive Monitoring

A dedicated team of asset health evaluators and train controllers monitor the health and status of wayside and train-borne equipment from the Operations Center in Perth.

Rio Tinto has about 221 locomotives equipped with the AutoHaul technology, for every locomotive that is on the network locomotive health status, alarms, and videos (collision detection events, level crossing obstruction events) are monitored. Activities that were previously performed by the driver while on board the train are now managed by the Rolling Stock Asset Health Evaluator Team, which remotely monitors the onboard status of assigned trains throughout their journey and process all onboard alarms and notifications raising maintenance request where required.

The AutoHaul system is designed to automatically stop the train for:

(1) Asset alarms from wayside equipment like dragging equipment detector or hot bearing detectors; (2) critical wayside and onboard equipment failure; (3) obstruction events from level crossing; and (4) collision events detected on the train.

Further Opportunities

This section introduces the future vision of Hitachi’s railway business division including establishing autonomous operation system.

Digital Value Proposition

Using the power of analytics, it is possible to visualize the vast amount of operational data available to identify trends and predict issues benefiting maintenance and operations. Maintenance strategy can shift from corrective maintenance to preventive maintenance in the short term and ultimately to predictive and prescriptive maintenance. Autonomous operations bring repetition, the advantage of every locomotive driving the same way through the network this makes the wear and tear patterns on locomotive and trackside repeatable and predictable, which can be mapped to benefit in preventative maintenance tactics. Longer-term machine learning through smart algorithms can highlight potential problems before they become serious issues that result in taking out assets for a prolonged period of time. This makes it possible to avoid a situation where assets such as vehicles and railroad tracks are unusable for a long period of time.

Many synergies can be expected by sharing the use cases across the freight, metro, regional, and high-speed projects conducted by Hitachi’s railway business division up to now into one standard companywide analytics platform.

Integrated Operations and Optimization by Offering Fully Integrated Solutions

The pit to port concept for mining offers a shift from the run when ready operating models to looking at demand and availability of dumpers and stockpiles; this will bring efficiencies to the entire supply chain process. The solutions highlighted below can be explored as steps to achieve this.

- Integrated traffic management system (TMS), which leverages off Hitachi train scheduling technology and interfaces with the port and mine, scheduling utilizing key inputs such as client demand on the type of iron ore blend, shipping schedule, and ore stockpiles at different mines to client demand to create a daily, weekly operating schedule;

- Train pacing and moving block functionality to improve throughput, conserve fuel, and reduce wear on the train while implementing operating schedule; and,

- Improvements to driving strategy engine (DSE) to handle different train configurations, for example, two or three head end leads, distributed power arrangement and different wagon weights depending on iron ore blend and type.

Connectivity

The Internet of Things (IoT) has the potential to expand transportation capacity, improving maintenance and yard operation. This, combined with long term evolution (LTE*2) and 5th generation (5G) technology provides an increase in bandwidth needed for powerful visualization tools that can process information in real time for business-critical decisions. Establishing relationships with market leaders in communications, Hitachi can expedite to the advanced market solutions to gain market share.

In remote regions like the Pilbara, these technologies can also unlock other opportunities to introduce functionality such as:

- Tablet-based human machine interfaces (HMIs) offering a safety integrity level (SIL) rated alternative to the current paper-and-voice-based method to take track possession;

- Tablet-based HMIs can also be used on track machines and high-rail vehicles to integrate them into the AutoHaul system architecture and improve safety;

- Minimize the installation on wayside infrastructure for new stations that localize maintenance teams to central locations, reducing theft, power consumption, and driver fatigue.

- *2

- LTE is a registered trademark of the European Telecommunications Standards Institute (ETSI).

Conclusions

This paper has presented an overview of the development of Rio Tinto’s heavy haul freight transportation system, AutoHaul, and the future prospects of Hitachi’s railway business division.

The advancements in freight technology through implementing the strategies and developing applications discussed will add value to heavy haul clientele, but these can also benefit other platforms like regional and intercity operations, as some of the challenges experienced are similar. These initiatives will lead to positive impacts not only for the client, but also on United Nation’s Sustainable Development Goals (SDGs), which have been committed to by Hitachi.

REFERENCES

- 1)

- Ansaldo STS, “Ansaldo STS Signs Framework Agreement with Rio Tinto Iron Ore in Australia” (Nov. 2010)

- 2)

- Ansaldo STS, “Ansaldo STS a Hitachi Group Company Proud its Technology Has Enabled Rio Tinto to Launch the World’s First Autonomous Heavy Freight Rail Operation” (Jul. 2018)

- 3)

- Rio Tinto, “Successful Rollout of AutoHaul Positions WA as Global Rail Technology Leader” (Jun. 2019)

- 4)

- The Australian Financial Review, “Rio Confident AI Will Unlock More Gains in WA Iron Ore Rail” (Nov. 2019)