Volume 70 Number 2 Industry Solutions in the New Normal EraDesigning Industry Solutions to Take on the Challenges of the New Normal

COVID-19 and other threats are bringing supply-chain disruptions and worldwide economic stagnation and creating a rapid rise in demand for automated, remote, and contact-free interactions. Hitachi is responding to this demand by using digital technologies. This issue looks at Hitachi technologies and initiatives assisting industry in the new normal.

Cover Story

Total Seamless Solutions Using Products, OT, and IT to Assist Industry in the New Normal EraUsing Digital Technologies to Connect Workplaces, Management, and Supply Chains

COVID-19 has greatly altered the values of people and society at large. Digital transformation is making rapid strides in the industrial sector. Masakazu Aoki, Hitachi's Executive Vice President talks about what sort of management approaches companies should be using in this new normal.

Manufacturing DX for the New Normal EraDigitalization of Manufacturing Accelerating after the COVID-19 Pandemic

Looking to recover from earnings that were hit hard by the effects of COVID-19, companies around the world are moving briskly to boost the pace of digitalization. Mr. Koichi Iwamoto, Research Associate at The Research Institute of Economy, Trade and Industry, discusses how Japanese manufacturing should handle this situation.

Japan's Digital Transformation and Manufacturing Strategies for the New NormalTaking Advantage of Integral Architecture to Establish Effective Design Practices and Robust Supply Chains

It is not uncommon to hear people talking as if manufacturing is finished in Japan. Not so, according to Professor Takahiro Fujimoto of the University of Tokyo. He talks about how manufacturing should adapt to the new normal, including where the strengths of Japanese manufacturing are to be found and what business strategies should be pursued.

Solutions Using Digital Technology to Link Workplace, Management, and Supply ChainTranscending Barriers between Different Operations and Companies to Optimize Entire Value Chains

Diversifying customer needs and the spread of COVID-19 are making “boundary” issues more apparent than ever. This article presents Hitachi's total seamless solutions for optimizing entire value chains and creating new business value in resolving these issues using digital technologies. It also presents the associated collaborative creation.

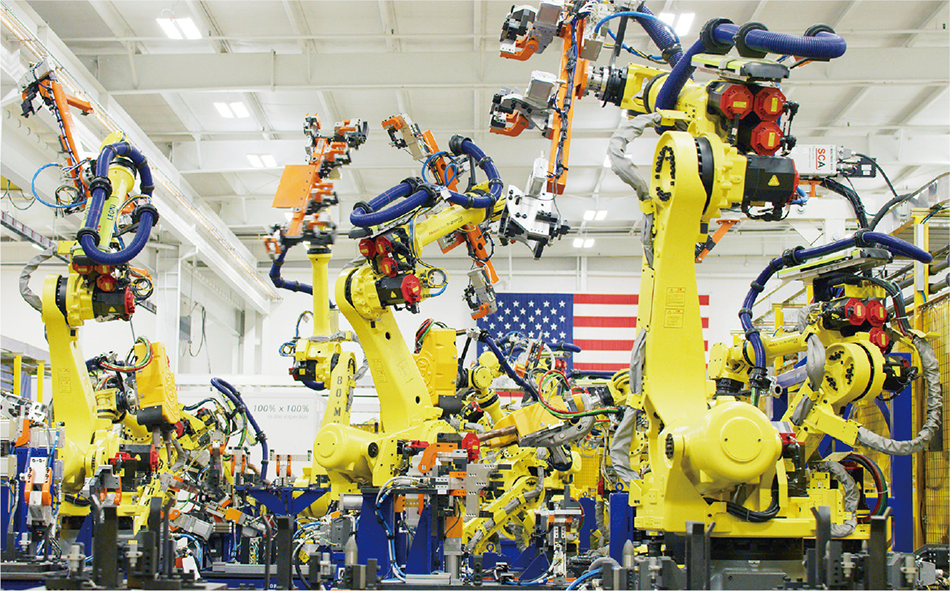

Transforming Industrial Workplaces with Robotics and AutomationBecoming a Robotic Systems Integrator for Next-generation Manufacturing

Automation and robotics touch every aspect of people's lives. In December 2019, JR Automation, a robotic systems integration business in the USA, joined Hitachi Group. This article describes the work that JR Automation is doing on innovation in industry and presents examples of collaborative creation prompted by the spread of COVID-19.

FEATURED ARTICLES

Industrial Services and Solutions Supporting Secure and Convenient Living

The novel coronavirus pandemic is confronting the world with the difficult task of maintaining economic activity while preventing the spread of infection. This section describes work to establish new value chains including technology for supply chains that places an emphasis on being non-contact and reducing the number of people involved, technology for regenerative medicine, and collaborative creation programs that deliver the maximum possible value to customers.

- Enhancing Industrial and Distribution Value Chains to Better Cope with New Normal

- Warehouse Automation Design for Labor-saving and Automation in Logistics Center Operations

- Autonomous Picking Robot System for Replacing Manual Labor at Logistics Centers

- Hitachi Digital Solution for Logistics: Enhancing Logistics in the New Normal to Improve Distribution Efficiency and Support Safe Operation

- DX Solution for Regenerative Medicine: Helping Usher in a New Era of Personalized Healthcare

- Combining Digital and Design Techniques to Collaborate with Customers on Value Creation for the New Normal

Manufacturing Solutions Assisting Quality and Safety

Problems such as global warming and shrinking workforces are becoming increasingly apparent throughout the world. This section looks at Hitachi’s solutions that focus on technologies for automation, remote work, and contact-free interactions, including solutions for manufacturing workplaces using video processing technologies and AI technologies, design assistance solutions for collaborative work in remote environments, and traceability management solutions to coordinate value chains.

- Hitachi Value Chain Solutions for Quality and Safety in Manufacturing

- Collaborative Design Solutions Helping Manufacturers Thrive in the New Normal

- Video Analysis Solution for Workplace Task Recognition

- Productivity and Quality Improvement Solution for Assembly and Machining WorkplacesUse of 4M Data Analysis in Manufacturing to Overcome Customer Challenges

- Solution for Building Production Lines with Dynamic Capability

- Comprehensive Traceability Technology for Value Creation in Manufacturing

- Use of AI to Enhance Steel Production Value Chain