COVER STORY:REPORTExploring Rail’s Future with Technology Inherited from the PastOne-Hundred-Year History of Hitachi’s Kasado Works

Early Days of Kasado Works

Kasado Works celebrated its 100th anniversary in May 2021. As a part of Hitachi, Ltd.’s Railway Systems Business Unit, it is involved in the production of rolling stock, from designing to manufacturing. Having split off from the Kuhara Mining Company in 1920, Hitachi acquired the Kasado shipyards of Nihon Kisen Co., Ltd. and commenced the production of steam locomotives and other rolling stock at the site, which is located in Kudamatsu, a city in Yamaguchi Prefecture. At that time, the Ministry of Railways was looking to electrify the Tokaido Line, planning to place orders for electric locomotives exclusively from overseas suppliers. Instead, Hitachi set out to develop its own large electric locomotives. This development presented a series of difficulties for Hitachi as its past experience had been limited to the manufacture of small electric locomotives used in mines. After countless processes of trial and error, however, Hitachi successfully completed its first prototype in 1924. The new locomotive was tested at the Ministry of Railways’ Omiya Factory and put through a series of test runs on the actual track, ultimately entering service on the Tokaido Line as the Class ED15 electric locomotive. By producing various types of rolling stock, Kasado Works has been contributing to a number of people traveling with this form of transportation ever since.

Rolling Stock Produced in Kasado

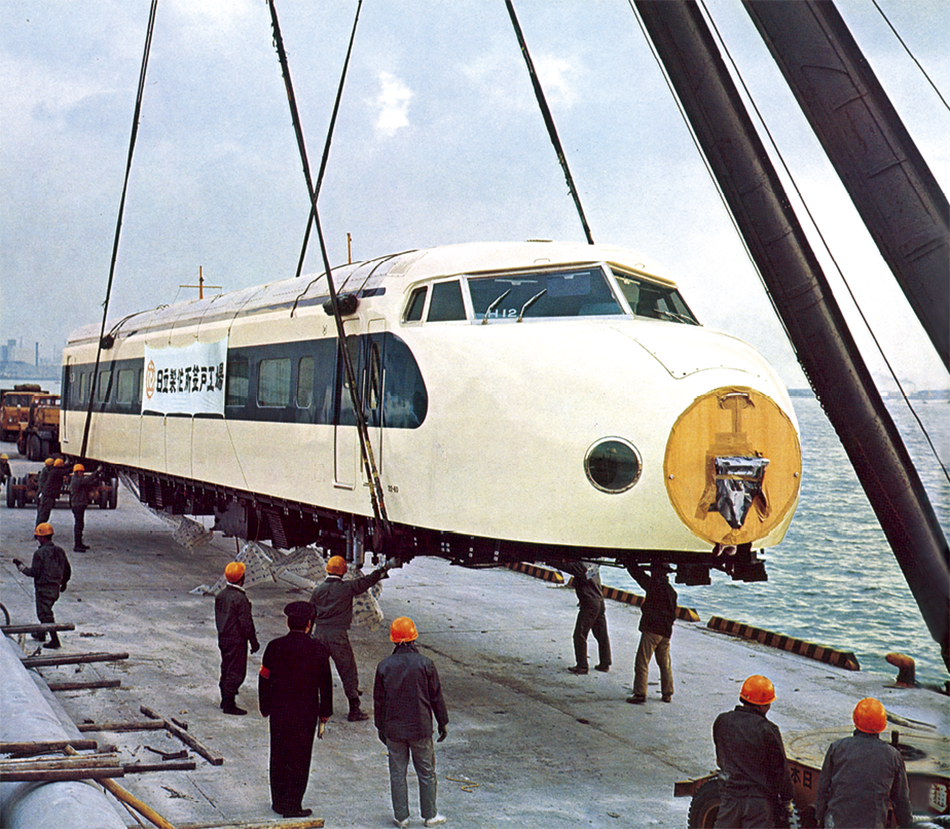

Kasado Works has produced a wide variety of rolling stock, from high-speed trains to commuter trains, over the hundred years of its history. Among those, perhaps the most well-known of all is the Shinkansen. The construction of the Tokaido Shinkansen line commenced in 1959 with a target speed of 200 km/h, which was the fastest in the world at that time. Hitachi completed a prototype in 1962 and went on to deliver 214 “0 series Shinkansen” rolling stock by 1970, with a reputation for high quality gained on a test track. The Shinkansen continued to evolve with series design changes, providing people with a form of transportation that is both comfortable and environmentally friendly.

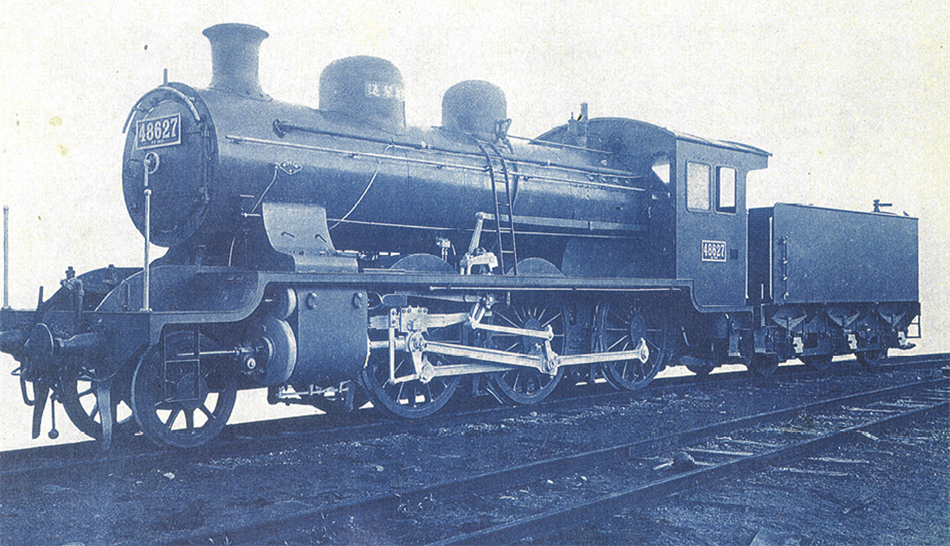

Meanwhile, some of the rolling stock models are still around, retaining their appearance from the past. Toward the end of the Meiji Era, the Tetsudoin Railway Authority (which subsequently became Japanese National Railways) introduced the new Class 8620 steam locomotives, designed based on large locomotives like the Class 8800 imported from the USA and some European nations such as the UK, Germany, etc. The development of Class 8620 had the purpose of playing a great role in establishing the technology for domestic locomotive production. Having as yet little experience in the industry, Kasado Works couldn’t win any orders from the Ministry of Railways at first. Following negotiations with Tetsudoin, however, it successfully built its own Class 8620 locomotive based on borrowed manufacturing plans and this in turn led to new orders. One of the Class 8620 locomotives that has been preserved in working condition is the number 58654 built at Kasado Works in 1922. This venerable old steam locomotive can still be seen at shows and other events courtesy of Kyushu Railway Company, celebrating its 99th birthday in 2021.

Monorail is another type of rolling stock that represents Kasado Works’ achievement. Since first licensing technology from Alweg, a firm in the Federal Republic of Germany, in 1960, Hitachi has gone on to develop its own monorails for urban transportation, with the Inuyama Monorail in 1962, two years after it started the production of monorails, and the Tokyo Monorail between Haneda Airport and Hamamatsucho in 1964. The cars for the Inuyama Monorail were also the first Hitachi railway rolling stock to be made from aluminum.

This was followed by the Kitakyushu Monorail opening as an urban mass transit system in 1985, the Osaka Monorail in 1990, the Tama Toshi Monorail in 1998, and the Okinawa Monorail in 2003. Kasado Works has also developed a driverless automatic train operation (ATO) system and functioned in the supply of monorails outside Japan, including the Palm Jumeirah Monorail in Dubai, United Arab Emirates in 2009 and the No. 3 monorail line for the Daegu Metropolitan Transit Corporation in the Republic of Korea in 2015. Production work is now underway in partnership with other production divisions on the development of a newly ordered monorail for the Republic of Panama.

Environmentally Friendly Manufacturing

Kasado Works has been working to improve the efficiency of its energy and resource use over recent years by upgrading its rolling stock manufacturing processes as part of the environmental measures to address concerns like climate change. A notable example is “the A-train” made from lightweight aluminum, a material with excellent recycling properties. The amount of electricity consumed in the production of each rolling stock has been reduced by 46% as a result of adopting friction stir welding, a technique that requires less heat than past practices.

Kasado Works also put emphasis on saving and reusing the necessary resources during the manufacturing process. For instance, the head shapes of high-speed trains were specially designed to minimize air resistance: Here, the adoption of a high-speed cutting technique that achieves a smooth exterior finish has reduced consumption of the putty used to fill in bumps and undulations by 89%, with use of the chemicals contained in paint also having been cut considerably. Additionally, Kasado Works achieved 100% recycling of water used on site in testing the waterproofing of carbodies, and managed to ensure almost all of the waste was reused by carefully sorting it, with only 0.1% going to landfill as of 2013.

Class 800 rolling stock being transported through Kudamatsu (top left) and Kentaro Masai, Hitachi Vice President and Executive Officer, shaking hands with city mayor Masuo Kunii in front of one of the trains (bottom right)

Class 800 rolling stock being transported through Kudamatsu (top left) and Kentaro Masai, Hitachi Vice President and Executive Officer, shaking hands with city mayor Masuo Kunii in front of one of the trains (bottom right)

Growing toward Worldwide Rolling Stock Manufacturing Plants

Hitachi has expanded its railway systems business from its base in Japan to numerous countries and regions, including Australia, North and South Americas, Africa, Asia, and so on. More recently, Hitachi has also established production facilities overseas, starting in 2015 with a plant at Newton Aycliffe in the UK, the nation known as the birthplace of the railway industry. It has also expanded its presence globally by welcoming Ansaldo Breda S.p.A (now Hitachi Rail S.p.A) and Ansaldo STS S.p.A (now Hitachi Rail STS S.p.A) to the group. Along with Kasado Works, these plants work day-in and day-out on manufacturing rolling stock for use around the world. Kasado Works has recently been working with the Newton Aycliffe Manufacturing Facility on the Class 800 high-speed train for the UK. It was hailed as a great achievement to have executed the transportation of the completed Class 800 rolling stock through the city from the plant to the docks for loading onto ships.

Drawing on its past successes and the experience built up over its 100-year history as well as the reliable skills that have been handed down over time, Hitachi’s Kasado Works will continue supporting the world’s railway systems through the manufacture of safe and comfortable trains.

- 1921

- Acquisition of the Kasado shipyards of Nihon Kisen Co., Ltd.

and its relaunch as Hitachi’s Kasado Works - 1922

- Completion of first electric locomotive

- 1924

- Completion of first large-scale electric locomotive to be made in Japan

- 1931

- Completion of first diesel locomotive (D1001 series)

- Completion of first gasoline-powered locomotive

- 1948

- Completion of Japan’s largest steam locomotive (Class C62)

- 1957

- Delivery of rolling stock to Indian Railways (Mumbai region)

- 1958

- Delivery of steam locomotives to Bolivia

- 1961

- Winning Okochi Memorial Production Prize

- 1962

- Completion of two Shinkansen prototype rolling stock

- Completion of Inuyama Monorail

- 1964

- Delivery of 0 series Shinkansen and 481 series rolling stock

- Opening of Tokaido Shinkansen and Tokyo Monorail

- 1977

- Completion of ML500 Maglev railcar

- 1982

- Delivery of rolling stock for Japanese National Railways, including 103-1500 series and 415 series AC/DC dual current units

- Manned testing of MLU001 Maglev railcar

- 1983

- Delivery of stainless steel rolling stock to national railway in South Africa

- 1984

- Completion of subway rolling stock for USA (MARTA)

- 1987

- Package contract received for 205 series rolling stock from East Japan Railway Company for the first time, following breakup and privatization of Japanese National Railways

- 1990

- Completion of 300 series “Nozomi” Shinkansen rolling stock for Central Japan Railway Company

- 1992

- Total number of Shinkansen rolling stock produced reaches 1,000

- 1994

- Good Design Award received for E1 and E351 series rolling stock for East Japan Railway Company and 10000 series rolling stock for Seibu Railway Co., Ltd.

- 1996

- Completion of 500 series Shinkansen rolling stock for West

Japan Railway Company - Opening of Kasado Works History Museum

- 1998

- Completion of first production model of 700 series Shinkansen

for Central Japan Railway Company - Partial opening of Tama Toshi Monorail between Tachikawa-Kita Station and Kamikitadai Station

- 1999

- Delivery of first A-train rolling stock 815 series commuter trains

supplied to Kyushu Railway Company - 2003

- Completion and delivery of rolling stock for Metropolitan Intercity

Railway Company (Tsukuba Express) - Completion and delivery of 800 series “Tsubame” Shinkansen

rolling stock to Kyushu Railway Company - 2004

- Delivery of 1000 series monorail to Chongqing Rail Transit

- Delivery of 700T series Shinkansen rolling stock to Taiwan High Speed Rail Corporation

- 2005

- Delivery of small monorail to Sentosa Development Corporation

- 2007

- Delivery of first Class 395 rolling stock for UK

- 2008

- Delivery of monorail to Nakheel PJSC in Dubai

- Delivery of 30000 series rolling stock to Seibu Railway Co., Ltd.

- 2009

- Commencement of commercial operation for Class 395 train in UK

- 2010

- Delivery of 15000 series rolling stock to Tokyo Metro Co., Ltd.

- 2012

- Signed formal contract for IEP in UK

- 2013

- Commencement of commercial operation for “Seven Stars in

Kyushu” train of Kyushu Railway Company - 2014

- Delivery of H5 series Shinkansen to Hokkaido Railway Company

- 2015

- Delivery of rolling stock for IEP in UK started

- 2017

- Delivery of 20000 series rolling stock to Sagami Railway Co., Ltd.

- 2018

- Received the Minister of Land, Infrastructure, Transport and Tourism Award for the A-train at the Global Environment Awards

- Delivery of N700S validation test model train to Central Japan Railway Company

- 2019

- Delivery of E956 Shinkansen (ALFA-X)

Delivery of rolling stock to Red Line project in Thailand - 2020

- Delivery of 17000 series (Yurakucho Line) and 18000 series (Hanzomon Line) rolling stock to Tokyo Metro Co., Ltd.

- Delivery of rolling stock for Line 1 of Ho Chi Minh City Metro in Vietnam

- MARTA:

- Metropolitan Atlanta Rapid Transit Authority

- CTRL:

- Channel Tunnel Rail Link

- IEP:

- Intercity Express Programme