Series: Green Solutions for Building a Hydrogen and Ammonia Supply Chain (2) Work on Development of Hydrogen Supply Chain for General and Industrial Use in Namie Town, Fukushima Prefecture

Highlight

As a form of energy that does not emit CO2 at the point of use, expanding the use of hydrogen is seen as playing a major role in decarbonization, enabling efficient energy use and offering opportunities for the storage of renewable energy.

Namie Town in Fukushima Prefecture has been quick to recognize hydrogen as a new energy source for the future and is pursuing a variety of related initiatives with the goal of making greater use of the hydrogen produced by the Fukushima Hydrogen Energy Research Field (FH2R), one of the world’s largest facilities for producing hydrogen from renewable energy. Hitachi has since 2022 been partnering with Namie Town on a demonstration project for promoting the use of hydrogen by general consumers and lowering the cost of use by industrial consumers.

This article presents an overview of the project and the plans for the future.

1. Introduction

Namie Town in Fukushima Prefecture suffered significant damage during the Great East Japan Earthquake that struck on March 11, 2011. The accident at Fukushima Daiichi Nuclear Power Station led to the abandonment of plans by Tohoku Electric Power Co., Inc. to build the Namie-Odaka Nuclear Power Plant in the area, forcing the town to make a shift toward non-nuclear sources of energy.

The prefecture, meanwhile, has embarked on the Fukushima Innovation Coast Framework, a plan for developing the industrial infrastructure of the prefecture’s coastal Hamadōri region that envisages a key role for using renewable energy as a source of power. This comes on top of the goal of generating energy from renewable sources equivalent to 100% or more of the prefecture’s primary energy demand by 2040 that was laid out in the March 2012 revision of the Fukushima Prefecture Vision for Promoting Renewable Energy, published in the aftermath of the earthquake and tsunami.

While all this was happening, Namie Town was quick to recognize the potential of hydrogen and developed the Hydrogen Town Namie plan, which seeks to make greater use of the hydrogen produced by the Fukushima Hydrogen Energy Research Field (FH2R), one of the world’s largest facilities for producing hydrogen from renewable energy. In doing so, they were pursuing an approach to community recovery and redevelopment in which hydrogen serves as a new source of energy.

As part of these efforts, Namie Town has partnered with Marubeni Corporation, Hitachi, Panasonic Corporation, and the Miyagi Consumer’s Co-operative Society. In July 2021, the five partners entered into the Cooperation Agreement Regarding Namie Town Revitalization Plan, Utilizing Hydrogen for Decarbonization. This agreement aims to bring about a comprehensive reconstruction and recovery in Namie Town, including contributing to the community recovery and redevelopment approach and RE100*1 industrial park while also encompassing regional revitalization and digital transformation (DX). Based on this agreement, Hitachi embarked in FY2022 on the Demonstration Project for the Development of a Hydrogen Supply Chain for General and Industrial Use and Adjustment of Hydrogen Supply and Demand, a project funded by the Ministry of Economy, Trade and Industry in its efforts to promote understanding of the energy transition and make structural improvements in the sector.

This article presents an overview of the demonstration project and the plans for the future.

- *1

- An international initiative in which companies seek to purchase the energy used in their business activities from 100% renewable sources.

2. Overview of Demonstration Project

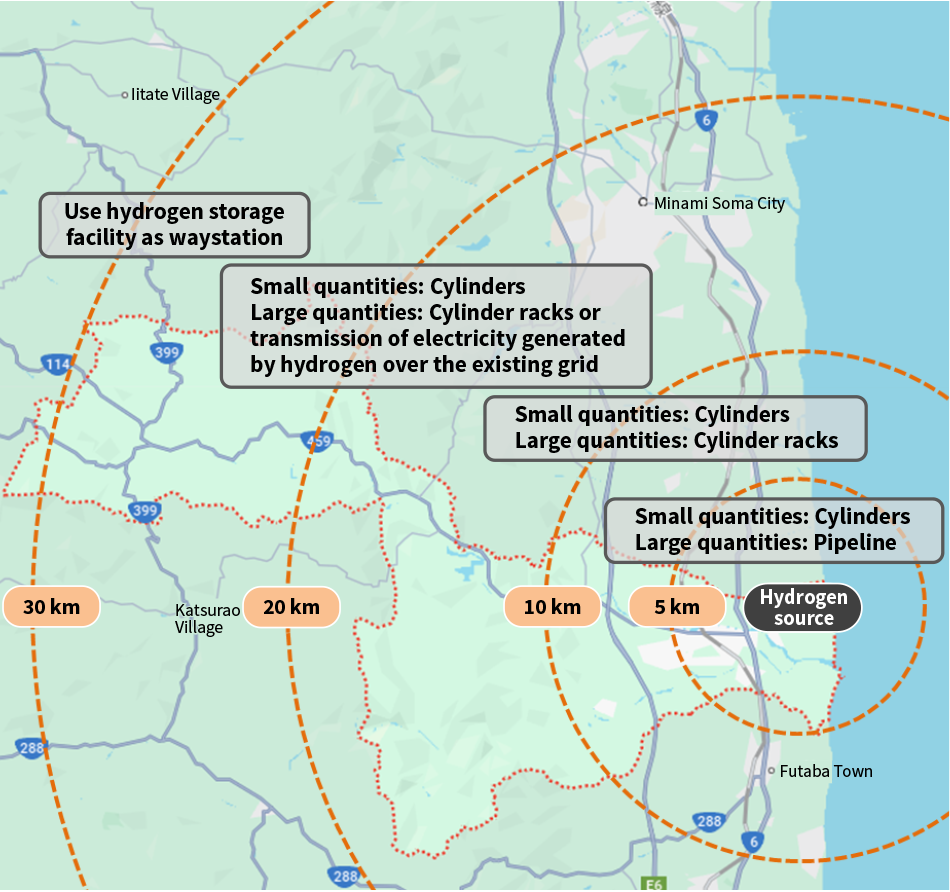

Figure 1—Suitable Distances for Different Forms of Hydrogen Transportation * Image courtesy of Google Maps. Google and Google Maps are registered trademarks of Google LLC.As the optimal solution for transporting hydrogen will likely be different depending on the quantity of hydrogen to be transported and the distance from the hydrogen source to the point of use, technical trials and economic assessments are needed for all the different forms of transportation.

* Image courtesy of Google Maps. Google and Google Maps are registered trademarks of Google LLC.As the optimal solution for transporting hydrogen will likely be different depending on the quantity of hydrogen to be transported and the distance from the hydrogen source to the point of use, technical trials and economic assessments are needed for all the different forms of transportation.

Development and implementation of a hydrogen supply chain requires that the challenges posed by the creation, transportation, and utilization of hydrogen be identified and resolved. In particular, Namie Town has been conducting technical trials of two models for the transportation of hydrogen: (1) The land transportation of hydrogen in trailers or cylinder racks and its transformation into electricity or heat at the point of use, and (2) The delivery of hydrogen to the point of use by running pipelines along existing power poles. High transportation costs are an issue for both options, with the former requiring special-purpose delivery vehicles and the latter requiring installation of the pipelines.

It can also be assumed that the optimal solution will depend on the quantity of hydrogen to be transported and the distance from the hydrogen source to the point of use (see Figure 1).

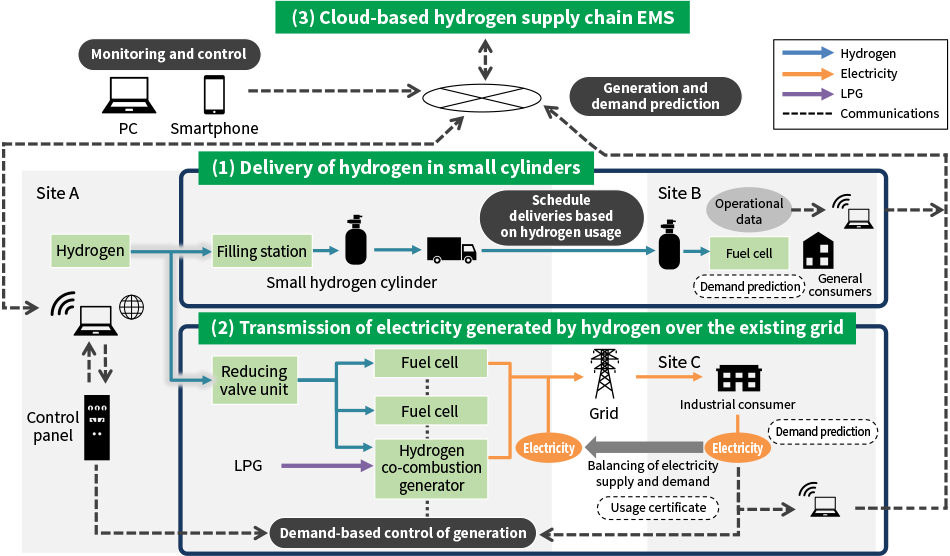

Accordingly, the demonstration project trialed two different forms of hydrogen energy distribution. These were the delivery of hydrogen in small cylinders for general consumers with comparatively low energy demand who are located close to the hydrogen source, and the transmission of electricity generated by hydrogen over the existing grid in cases where the point of use is distant from the hydrogen source and for industrial use where energy demand is comparatively high. The project also included the implementation of an energy management system (EMS) for supervisory monitoring and control of these two forms of hydrogen energy distribution (see Figure 2).

Figure 2—Overview of Demonstration Project EMS: energy management system, LPG: liquefied petroleum gasThe demonstration project adopting three different approaches to “transportation” for enabling the hydrogen society of the future.

EMS: energy management system, LPG: liquefied petroleum gasThe demonstration project adopting three different approaches to “transportation” for enabling the hydrogen society of the future.

2.1 Delivery of Hydrogen in Small Cylinders for General Consumers

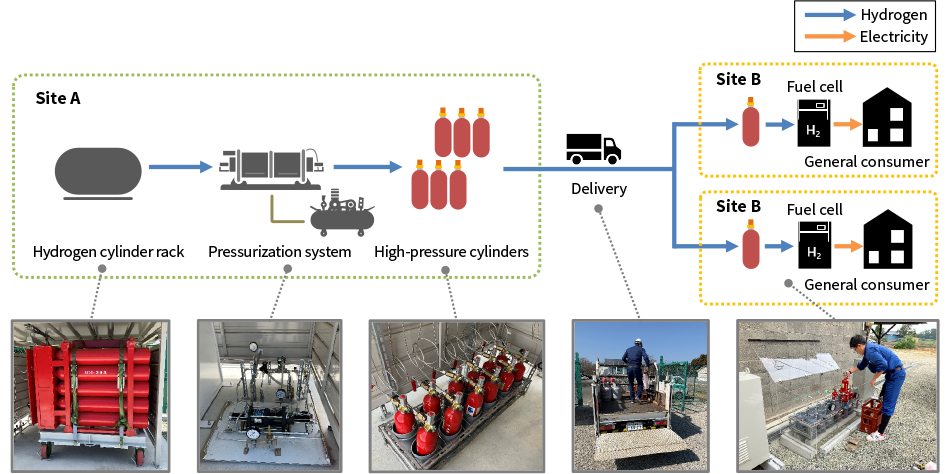

The demonstration project is using small cylinders to supply hydrogen to households and other general consumers with comparatively low energy demand, adopting JC lung*2 20-L cylinders (2.8-L internal capacity) made by JFE Container Co., Ltd. for this purpose. While these small cylinders do not have as much capacity as a hydrogen cylinder rack or conventional hydrogen cylinder, they are small and light enough to be carried by hand. As this means they can be loaded onto delivery vehicles for transportation along with other goods, distribution costs can be minimized by the use of existing household delivery arrangements. Hydrogen from the small cylinders can also be used to generate electricity in pure hydrogen fuel cells installed in the recipient households or other general consumer premises (see Figure 3).

For the FY2023 demonstration project, these small cylinders were used to deliver hydrogen to three general consumer premises in Namie Town over a three-month period. A total of 180 cylinders were delivered during this time and the fuel cells generated 56 kWh of electric power. A quantitative assessment indicated that the economics of this approach would be comparable to existing energy sources and hydrogen distribution practices. The trial results also shed light on the operational issues associated with using small cylinders for hydrogen distribution and how they could be resolved.

For the FY2024 demonstration project, the intention is to trial efficient cylinder delivery over a wider area by expanding distribution to include Minami Soma City to the north of Namie Town and by introducing JC lung 30-7 (6.8-L internal capacity) cylinders, also made by JFE Container.

Figure 3—Flowchart of Hydrogen Delivery Using Small Cylinders The small cylinders are filled with hydrogen and delivered to households and other general consumers. Fuel cells transform the delivered hydrogen into electric power for the consumer to use.

The small cylinders are filled with hydrogen and delivered to households and other general consumers. Fuel cells transform the delivered hydrogen into electric power for the consumer to use.

- *2

- JC lung is a registered trademark of JFE Container Co., Ltd. in Japan.

2.2 Transmission of Electricity Generated from Hydrogen over Existing Grid for Industrial Users

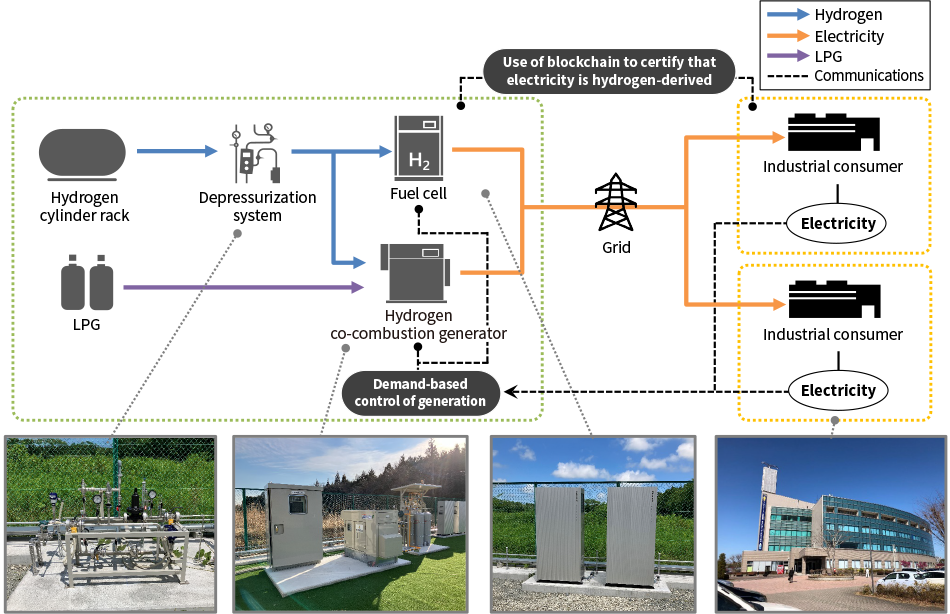

Rather than supplying hydrogen directly from the hydrogen source to physically distant factories and other industrial consumers with comparatively high energy demand, the demonstration project trialed the approach of using hydrogen to generate electricity for transmission over the existing distribution grid. In practice, this involved acquiring data on electricity use by industrial consumers and testing whether supply and demand could be balanced by controlling the output of pure hydrogen fuel cells and hydrogen co-combustion gas engine generator based on the fluctuations in demand. Practices for certifying that the electricity used by a consumer was derived from hydrogen energy were also verified by measuring and collecting electricity data in real time from both consumers and suppliers and by using a blockchain format that is not vulnerable to tampering (see Figure 4).

The FY2023 demonstration project targeted three industrial consumers in Namie Town and ran over a three-month period, verifying that supply and demand could be balanced using a pure hydrogen fuel cell and hydrogen co-combustion gas engine generator*3 by adjusting output in real time based on fluctuations in demand. Over the period of the trial, the pure hydrogen fuel cell generated 405.3 kWh of electric power and the gas engine generator generated 61.8 kWh. Total hydrogen consumption was 304.9 Nm3. The trial also demonstrated that control of the two different forms of generation in tandem could satisfy demand with a response accuracy of over 90%*4 when the demand did not exceed 16 kW, their combined maximum output.

For the FY2024 demonstration project, the scope of electricity supply will be expanded to include Minami Soma City and additional supply infrastructure will be incorporated in the form of photovoltaic power generation and battery storage. Plans also include developing and testing practices for achieving a best-mix of renewable energy supply by seeking to minimize cost and CO2 emissions based on the prediction of photovoltaic output and power use by industrial consumers.

Figure 4—Flowchart of Electricity Transmission over Existing Grid Using Hydrogen for Generation The output of the fuel cell and hydrogen co-combustion generator are controlled based on demand from industrial consumers.

The output of the fuel cell and hydrogen co-combustion generator are controlled based on demand from industrial consumers.

- *3

- A prototype generator powered by a blend of up to 50% hydrogen and liquefied petroleum gas (LPG) in terms of relative calorific value.

- *4

- Ratio of the combined generation output to electricity demand, expressed as a percentage.

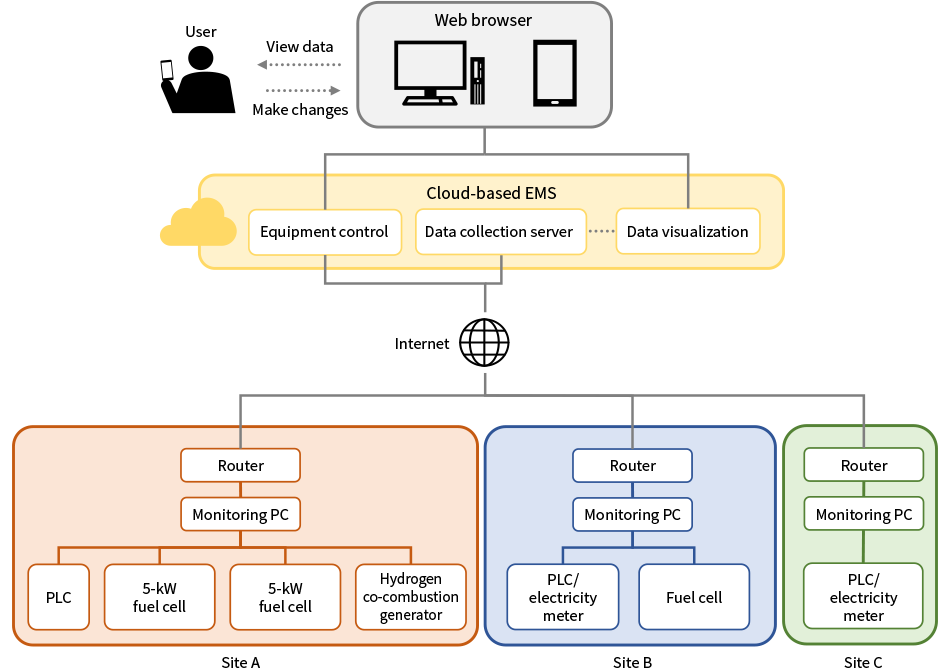

2.3 Cloud-based EMS

The demonstration project included the implementation of a cloud-based EMS for the supervisory monitoring and control of the two forms of hydrogen energy delivery described above. Measurement data from the participating sites is forwarded via the Internet from the installed monitoring PCs to a cloud-based data server. The data held on the data server can be viewed using a web browser and the same screen can be used to control the operation of the pure hydrogen fuel cells installed at general consumer premises as well as the generation systems used for industrial users (a pure hydrogen fuel cell and hydrogen co-combustion gas engine generator) (see Figure 5).

Figure 5—Block Diagram of Cloud-based EMS PLC: programmable logic controllerThe cloud-based EMS was implemented with a view to reducing the operational workloads of both the energy supplier and consumer and provides the ability to monitor and control generation plant from a browser.

PLC: programmable logic controllerThe cloud-based EMS was implemented with a view to reducing the operational workloads of both the energy supplier and consumer and provides the ability to monitor and control generation plant from a browser.

When delivering hydrogen in small cylinders, new deliveries to general consumers need to be made before their remaining hydrogen runs low, which depends on how much they use. In the demonstration project, a function was provided in the cloud-based EMS to recommend when general consumers should receive their next cylinder delivery based on their level of remaining hydrogen, which is estimated from the initial hydrogen delivery quantity calculated from the cylinder filling pressure and the operating conditions of the pure hydrogen fuel cell installed at their premises.

For the transmission over the existing grid of electricity generated by hydrogen, the demonstration project tested practices for transmitting hydrogen energy (the electrical output of a fuel cell and hydrogen co-combustion gas engine generator) with a timing and quantity that matches the demand from industrial consumers. To help them achieve decarbonization, however, there was also a need to certify that the electricity they use really is derived from hydrogen, and to do so in a form that is not vulnerable to tampering. The project adopted a blockchain method for this purpose. This certifies hydrogen use by using the blockchain to record electric power use by the industrial consumers and generation plant output and by matching records that have the same timestamp.

For the FY2024 demonstration project, photovoltaic power generation infrastructure and a battery storage system will be added and combined with the pure hydrogen fuel cell and gas engine generator to form a generation balancing group. The intention is to implement control logic on the cloud-based EMS for controlling the output of the adjustable power sources in the group to ensure that actual generation matches the predetermined generation plan.

3. Conclusions

This article has described work being done to establish a hydrogen supply chain at Namie Town in Fukushima Prefecture as it seeks to rebuild from the Great East Japan Earthquake. While hydrogen faces a multitude of technical and systemic challenges across the different phases of creation, transportation, and utilization, it is expected to enter widespread use in the future as a new energy source that will help society move toward carbon neutrality. Through the development and delivery of “digital and green” solutions, Hitachi is working to overcome the challenges facing hydrogen and will continue contributing to the Hydrogen Town plan to help make society carbon neutral.

Acknowledgements

The Demonstration Project for the Development of a Hydrogen Supply Chain for General and Industrial Use and Adjustment of Hydrogen Supply and Demand described in this article benefitted considerably from the assistance of Namie Town and a number of other municipalities and companies. The authors would like to take this opportunity to express their deepest gratitude.

REFERENCES

- 1)

- Hitachi News Release, “Commencement in Namie Town of Trial Operation of Demonstration Project for the Development of a Hydrogen Supply Chain for General and Industrial Use and Adjustment of Hydrogen Supply and Demand,” (Sept. 2022) in Japanese

- 2)

- “Aiming for Nationwide Application of Tomiya City’s Model of Low-Carbon Hydrogen Supply Chain,” Hitachi Review, 72, pp. 25-33 (Mar. 2023)