Smart Life Solutions for People EverywhereDevelopment of Home Appliances for Better QoL through Customization, Automation, and Ease-of-use

1. Introduction

Economic growth in emerging nations over recent years has been accompanied by rising energy demand, leading to the introduction of energy efficiency labeling schemes for home appliances. In Japan and other developed nations, meanwhile, aging populations are posing a problem in terms of maintaining and strengthening the workforce. As a result, these countries, Japan included, have seen an increasing number of women entering the workforce, with the number of dual-income households exceeding those with a stay-at-home housewife. Growing lifestyle diversity is also evident, and the number of single-person households is increasing. Given these circumstances, Hitachi, along with its pursuit of energy efficiency as an important core measure of home appliance performance, is also seeking to meet the individual needs of the people who actually use its products, developing features that enhance their quality of life (QoL) by solving life problems.

Hitachi has been highly acclaimed publicly for its energy efficiency, including winning the 2018 Chairman Prize of the Energy Conservation Center Japan (ECCJ) at the Energy Conservation Grand Prize event for a refrigerator with a vacuum compartment and the 2018 Technology Award of the Japan Society of Refrigerating and Air Conditioning Engineers for a compressor (an important component in appliances).

In its efforts to improve QoL, Hitachi is addressing: (1) customization to adapt to increasingly diverse lifestyles and needs, and (2) automation and enhancements in ease-of-use with the aim of making housework quicker and easier. It is also focusing its research and development capabilities on technologies that support these aims, for analysis, mechanical design (weight reduction), sensing, and control.

This article presents examples of research and development work on technologies that enhance QoL for four different products. It describes the use of analysis-led design to equip the Selectable Zone refrigerator with a new customizable layout; how a lightweight cordless stick vacuum cleaner was given lighter weight and greater suction power to make it easier to use; the automatic dispenser for liquid detergent and fabric softener in the Beat Wave Wash washer dryer and its AI-based washing feature that controls the wash cycle automatically based on actual conditions; and the Frost Wash Fan Robo feature for room air conditioners that automatically cleans the dust that builds up on the fan.

2. Refrigerator with Selectable Zone Feature

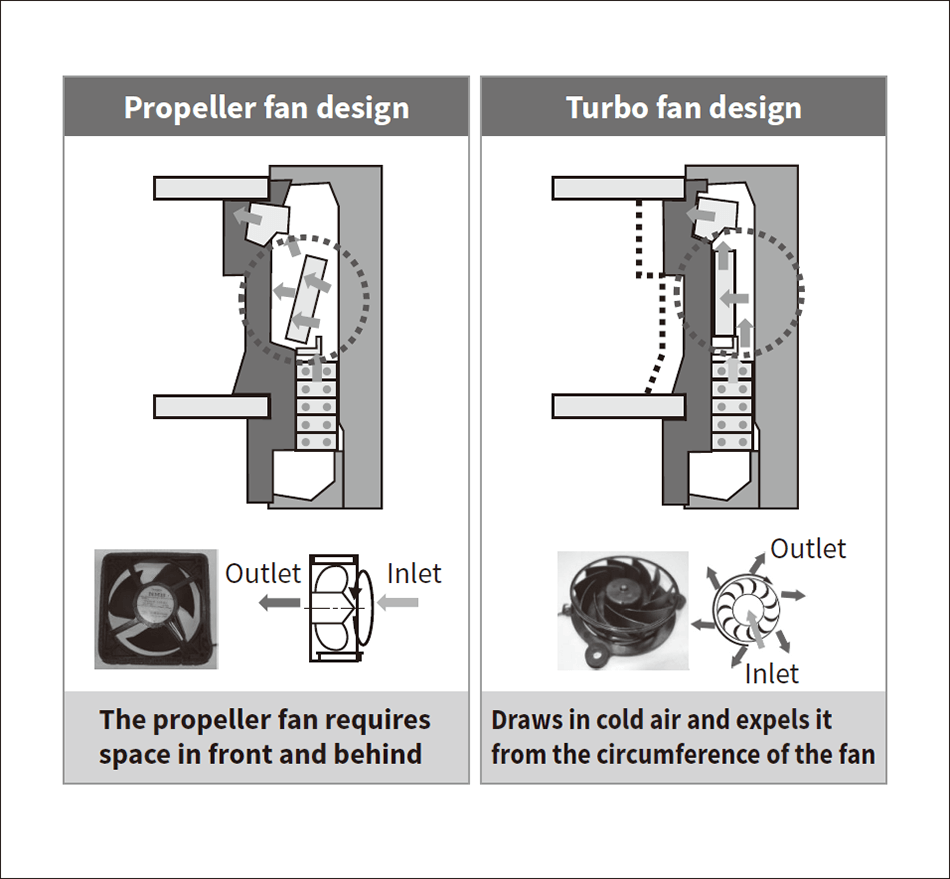

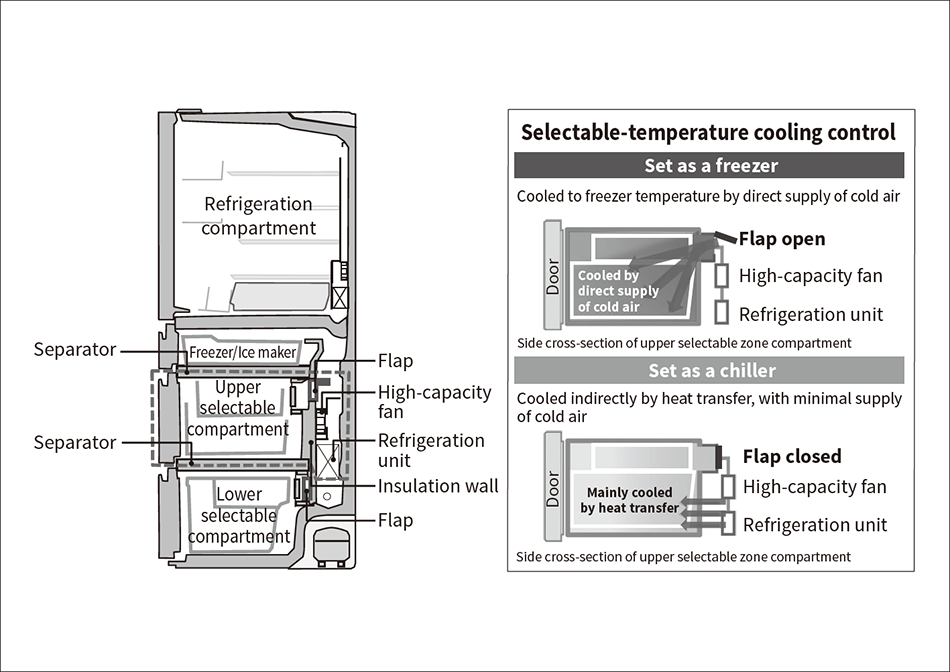

Fig. 1—Schematic Diagram of Selectable Refrigeration System The temperature ranges of the selectable compartments are controlled using the fan and flaps.

The temperature ranges of the selectable compartments are controlled using the fan and flaps.

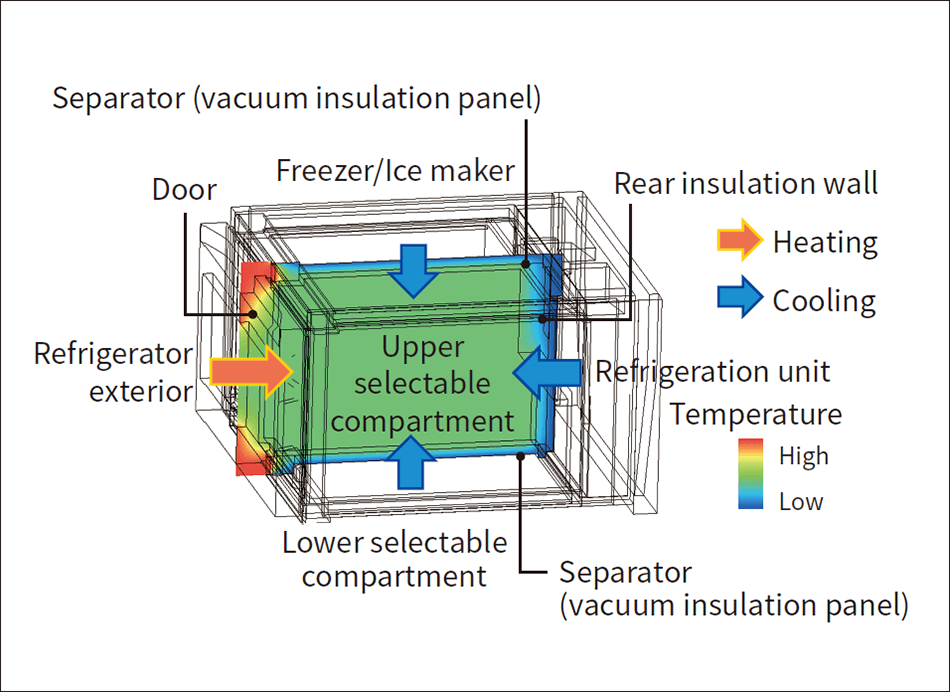

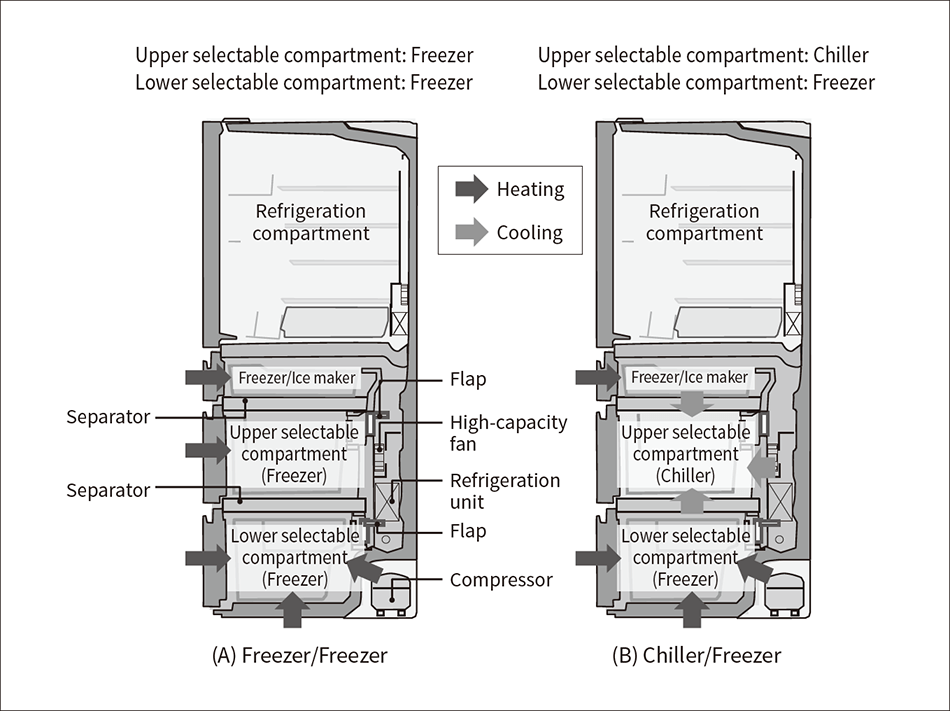

Fig. 2—Heat Flows in Selectable Compartments Whereas a large amount of ambient heat enters the compartments in case (A) (both compartments used as freezers), the upper selectable compartment is cooled from three sides in case (B) (compartments used as chiller and freezer respectively).

Whereas a large amount of ambient heat enters the compartments in case (A) (both compartments used as freezers), the upper selectable compartment is cooled from three sides in case (B) (compartments used as chiller and freezer respectively).

Hitachi has developed the Selectable Zone feature that provides two selectable compartments (pull-out drawers) in the lower section of the refrigerator. Users can choose whether to use each of these as either a freezer, chiller, or vegetable compartment depending on their needs. Getting this feature to work required channels for cold air flow and a configuration of insulation and thermally conductive material that would allow each of the selectable compartments to be operated in either the freezer or the chiller temperature range. Figure 1 shows a diagram of the selection system. The temperature ranges can be adjusted by using the fan and two flaps at the rear of the refrigerator to control the flow of cold air to the selectable compartments. When operating a compartment as a freezer, the system keeps the flap open so that cold air from the refrigeration unit can cool it directly. When operating as a chiller, the flap is mainly kept closed and the compartment is chilled by means of thermal conduction through the insulating wall at the rear, without direct entry of cold air into the compartment. The following explains the thermal flows for the two main temperature range settings and the issues that arose in implementing the system (see Figure 2).

Figure 2(A) shows a refrigerator in which both selectable compartments are set to the freezer temperature range. This configuration requires a high level of cooling performance because the large difference between the compartment and ambient air temperatures drives a high level of inward heat flow from the environment. Moreover, because heat enters the lower selectable compartment from the underside of the refrigerator and the compressor, it requires a greater flow of cold air than the upper compartment. This in turn requires that the channels provided for this purpose can supply a large amount of cold air from the refrigeration unit to the two selectable compartments.

Figure 2(B) shows a refrigerator in which the upper selectable compartment is set to the chiller temperature range and the lower to the freezer temperature range. The upper selectable compartment (chiller temperature range) is surrounded on three sides by components that operate at the freezer temperature range, with the freezer and ice maker above, the other (freezer temperature range) selectable compartment below, and the refrigeration unit to the rear. Maintaining the chiller temperature range under these conditions requires a design with an appropriate mix of insulation and thermally conductive material.

Consumer demand for refrigerators with a large capacity that look small from the outside means that the appliances need to pack their components into a small space while also dealing with the challenges of air circulation and insulation described above. Accordingly, Hitachi has been conducting analyses and other studies utilizing three-dimensional thermal fluid analysis during the initial development phases.

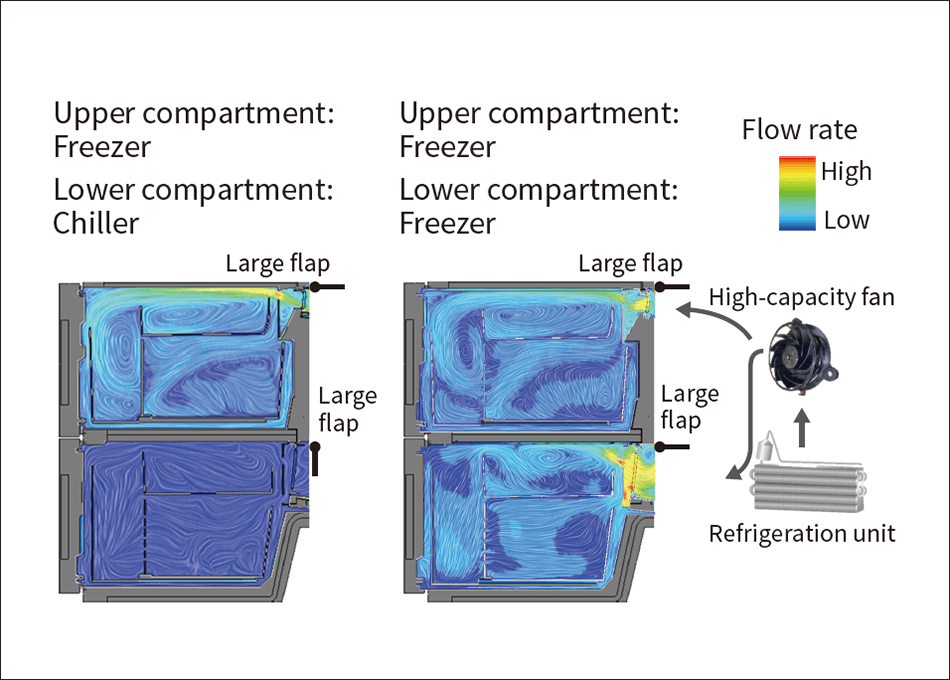

To improve air circulation, flaps with a large cross-section are used in the upper and lower compartments to reduce losses in the flow channels. Figure 3 shows how three-dimensional fluid dynamics was used in the design of these channels to analyze the flow rates of fan-driven cold air to these compartments. The results indicated the importance of the channels through which air returns to the refrigeration unit and prompted changes to the layout of these return channels for the upper and lower compartments. Running the return channel for the lower compartment along the front of the refrigeration unit reduced flow resistance and resulted in an air circulation system that delivered cold air to all corners of the interior while also delivering more air to the lower compartment. Meanwhile, replacing the previous propeller (axial) fan with a new turbo (centrifugal) fan and changing the direction of discharge eliminated the space downstream of the fan and enabled it to fit into a small space (see Figure 4).

Next, because the separators above and below the upper selectable compartment have a large surface area, and to prevent over-chilling of the refrigeration compartment, highly effective vacuum insulation was adopted. At the same time, the performance of the rear wall insulation was chosen to ensure the correct amount of cooling via heat transfer to the refrigeration unit, which also helps keep the compartment at the chiller temperature. This rear wall insulation has a complex shape because it also forms part of the air flow channel noted above. Accordingly, its shape was designed based on a three-dimensional thermal analysis, with polystyrene foam being used for its insulation performance and ease of forming. The results indicated that the temperatures of the selectable compartments are determined through a fine balance of heat inflows, and that it is possible to keep the upper selectable compartment at the correct chiller temperature when the lower compartment is configured to use the freezer temperature range, as in Figure 5. The use of vacuum insulation for the separators above and below the selectable compartments also helped increase the refrigerator capacity by keeping the separators thin while still providing the required level of insulation.

In this way, development proceeded efficiently thanks to the use of three-dimensional thermal fluid analysis during the initial development phases of this new function for selectable temperature ranges.

Fig. 3—Three-dimensional Fluid Dynamics Analysis The flow channel design analyzed here delivers cold air to all corners of the compartment, including when both compartments are set as freezers.

The flow channel design analyzed here delivers cold air to all corners of the compartment, including when both compartments are set as freezers.

3. Easy-to-use Lightweight Cordless Stick Vacuum Cleaner

This section describes the successful reduction in the body weight and suction head of a lightweight cordless stick vacuum cleaner that was designed to make everyday cleaning easier, and also the development of the small and lightweight TR high-performance motor housed in the cleaner to drive the fan.

3.1 Weight Reduction

A variety of measures were adopted on the body and suction head of a lightweight cordless stick vacuum cleaner to reduce its weight from 2.1 kg to 1.4 kg.

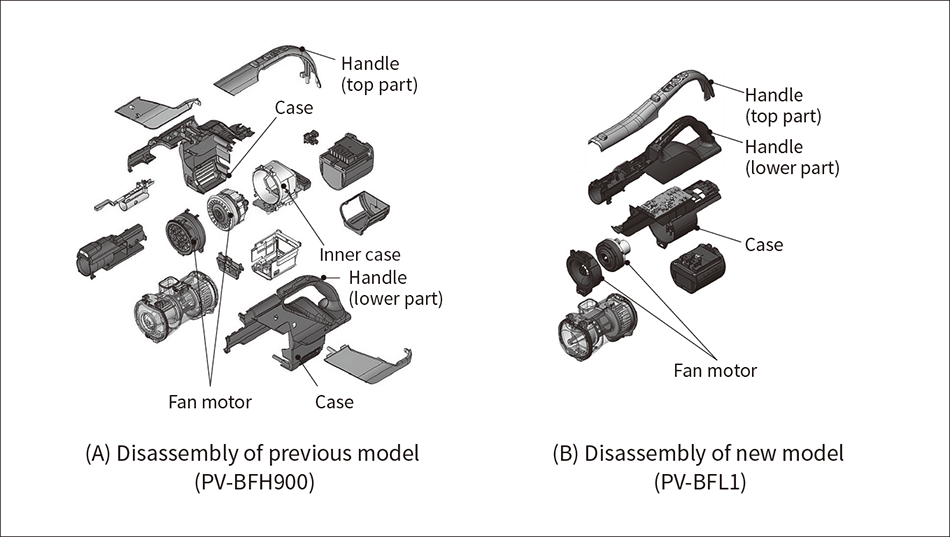

The internal layout of the cleaner was reconfigured to reduce the number of components, including the combining of parts in some cases. Figure 6 shows a comparison of the parts used in the previous and new models, with the new model having only a third as many parts as its predecessor. One example of how this was done is that, whereas the exterior of the fan motor was covered by a fireproof inner case in the previous design, and this in turn was built into the outer shell of the cleaner, the new design uses a fireproof material for the outer shell of the cleaner so that it can serve the same purpose. In other words, the weight of this inner case has been eliminated by fitting the fan motor into the cleaner without any inner casing.

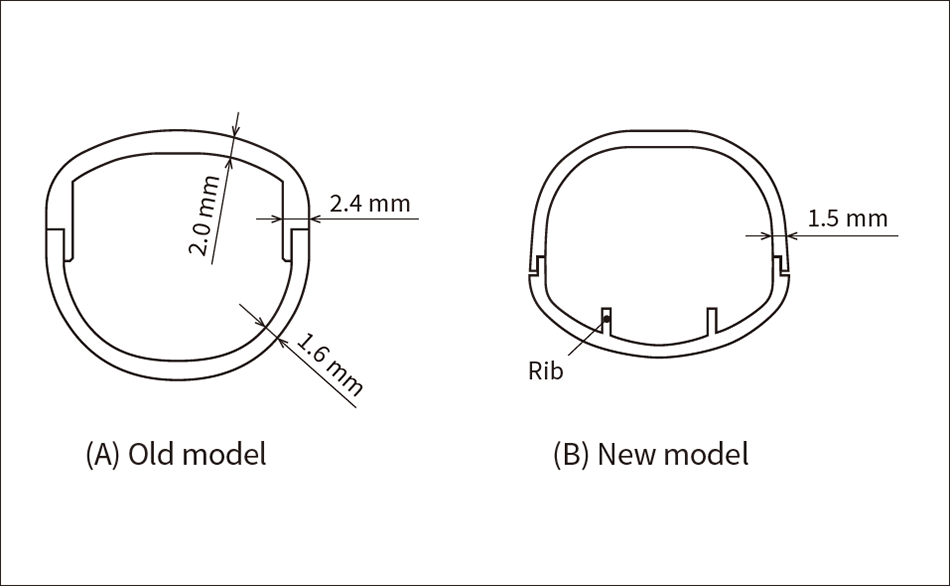

Another change was the use of thinner parts in the handle. Figure 7 shows cross sections of the old and new handles, both of which are made up of separate upper and lower pieces. Whereas the thicknesses on the old design were 2.0 mm and 1.6 mm respectively, the new design reduced both to 1.5 mm without compromising strength through the use of a more circular shape for the upper part and by adding a bare minimum of ribbing to the lower part.

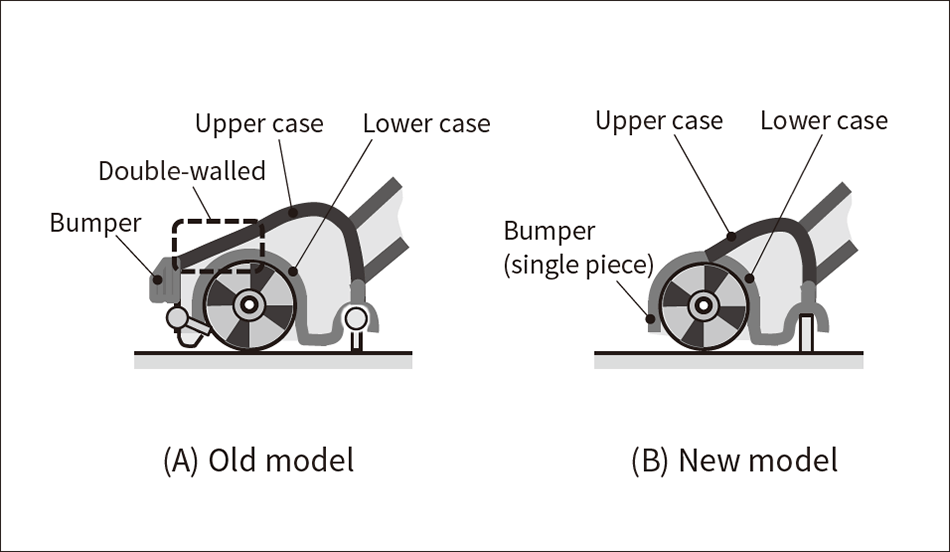

The weight of the suction head was also reduced. This part is important for appliance usability because of its location at the end of the suction tube, a long way from the user’s handgrip, which means that its weight has a large effect on how the vacuum cleaner feels when picked up. Figure 8 shows a cross-section of the suction head.

The outer shell of the suction head is primarily made up of upper and lower cases and a bumper. In the old design, the upper case entirely covered the lower case with the bumper being sandwiched between the two at the front. This arrangement results in a double-wall structure at the front of the suction head where the upper and lower cases are close together. The design of this outer shell was modified in the new cleaner to make it lighter by shrinking the front of the upper case and having the top of the lower case take over the role of providing the outer shell. The design was also kept simple and the weight reduced further by building the bumper into the lower case.

Fig. 6—Comparison of Old and New Vacuum Cleaner Designs The new model has only one-third as many parts as its predecessor.

The new model has only one-third as many parts as its predecessor.

3.2 Development of Small and Lightweight TR High-performance Motor

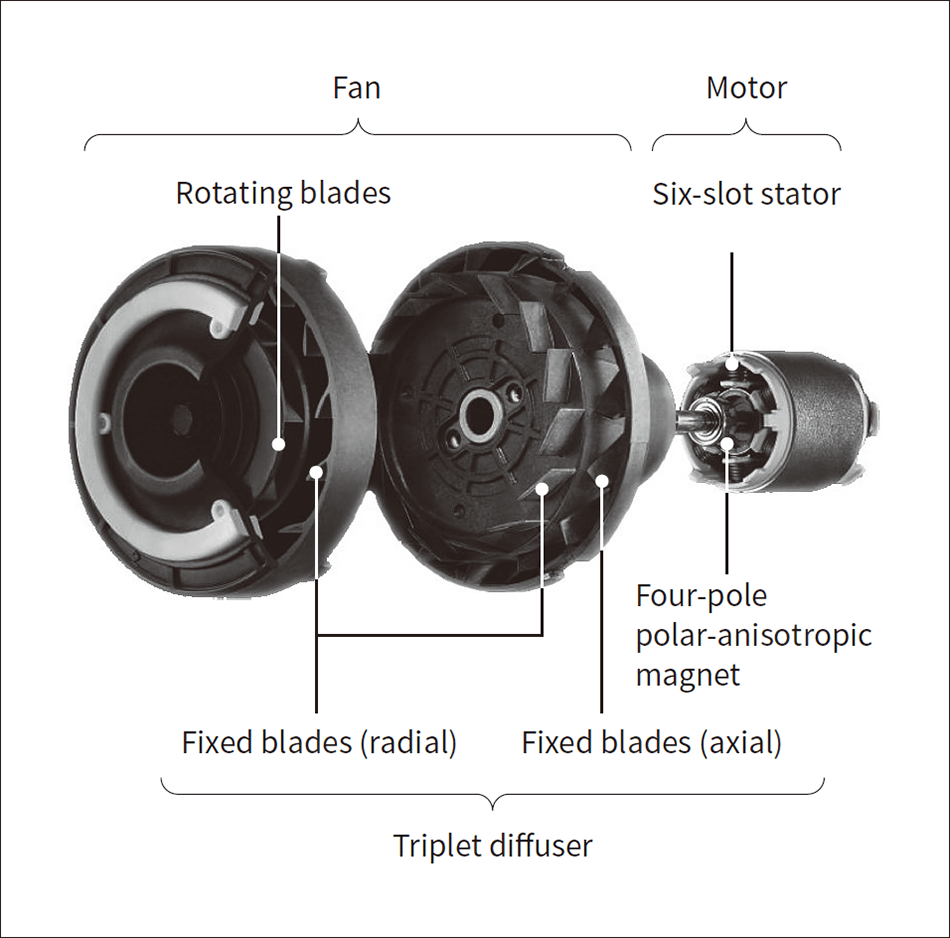

The fan motor is the source of a vacuum cleaner’s suction power, being made up of a fan that generates the flow of air and the motor that drives it. The technologies developed for each of these are described below.

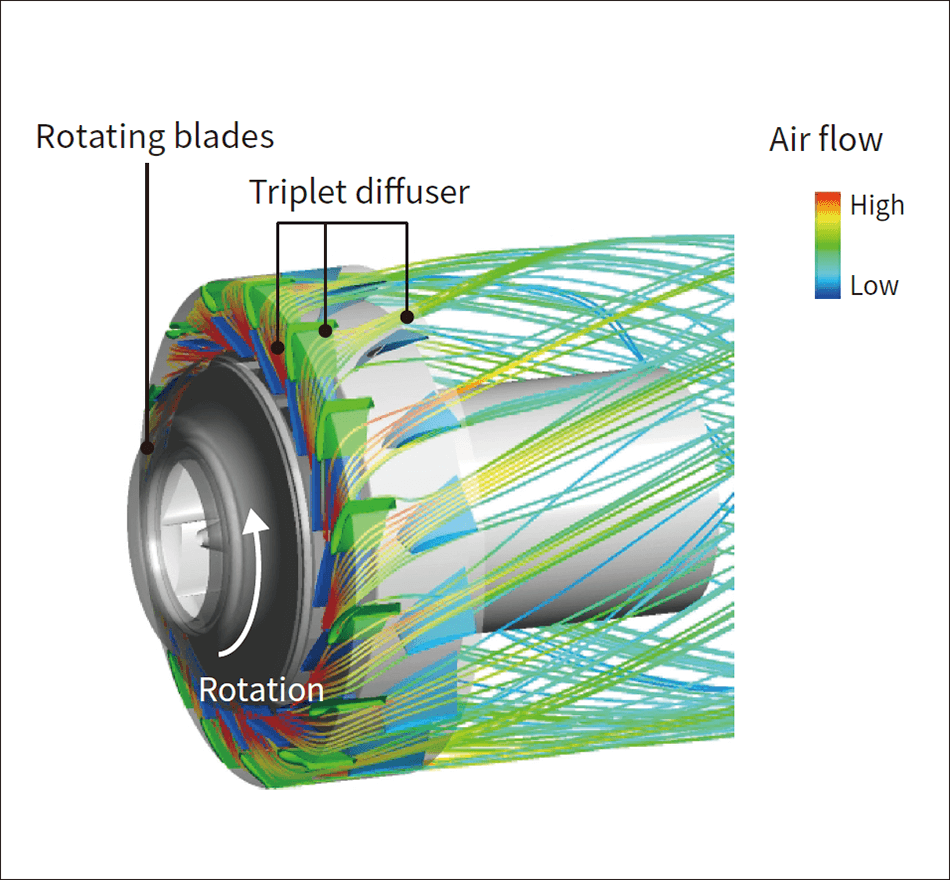

As shown in Figure 9, the fan is made up of rotating and fixed blades. For this new model, Hitachi developed its proprietary triplet diffuser that has three sets of fixed blades. This reduces losses by minimizing the radial component of the air velocity, having the high-speed air discharged from the rotating blades pass through two sets of fixed blades attached to the circumference of the rotating blades as well as fixed blades with blades oriented in the axial direction (see Figure 10). The fixed blades were developed by using three-dimensional fluid dynamics to analyze how to minimize separation caused by the rotational flow generated by the blades. This included the adoption of a three-dimensional blade profile for the final-stage fixed blades (which also serve as supports for the casing) based on consideration of the three-dimensional flow from the second stage of fixed blades. This delivers a high level of power by providing efficient control of the high-speed air flow from the rotating blades.

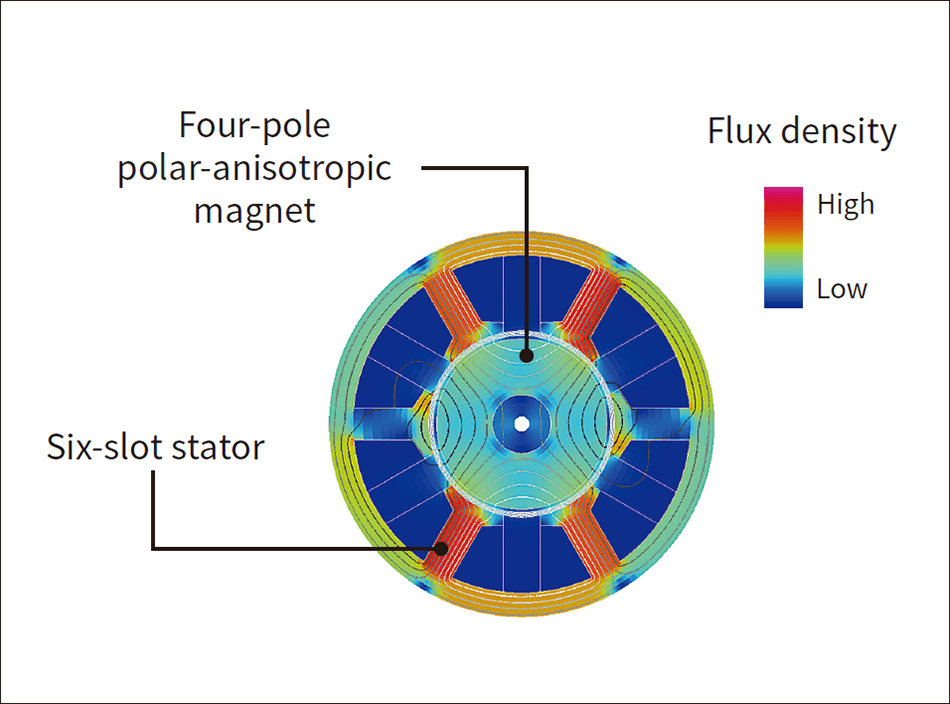

The motor features a four-pole polar-anisotropic magnet and six-slot stator, with small size, light weight, and smooth high-speed operation achieved through optimization of the magnetic circuit (see Figure 11).

In this way, Hitachi succeeded in designing an easy-to-use vacuum cleaner that combines light weight with powerful suction.

4. Beat Wave Wash Top-loading Washer Dryer

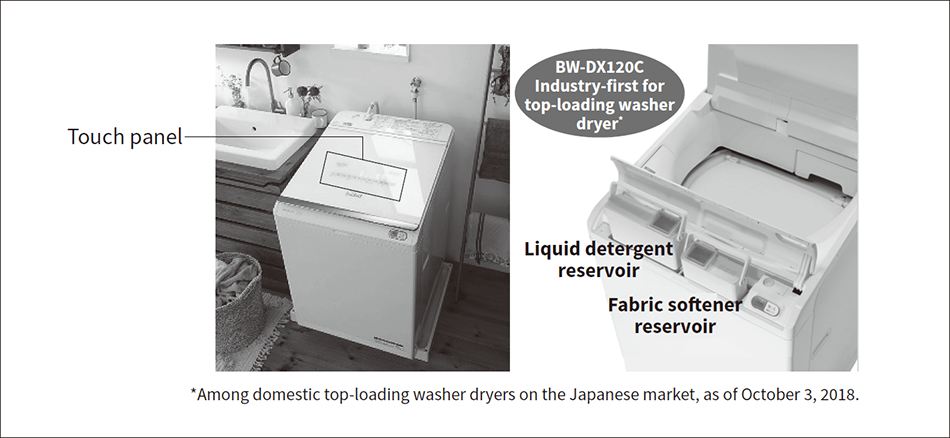

This section describes the development of an automatic dispenser for liquid detergent and fabric softener, an industry-first* for a top-loading washer dryer and the AI-based washing feature that automatically controls the wash cycle using sensors to detect the washing conditions.

- *

- BW-DX120C. Among domestic top-loading washer dryers on the Japanese market, as of October 3, 2018.

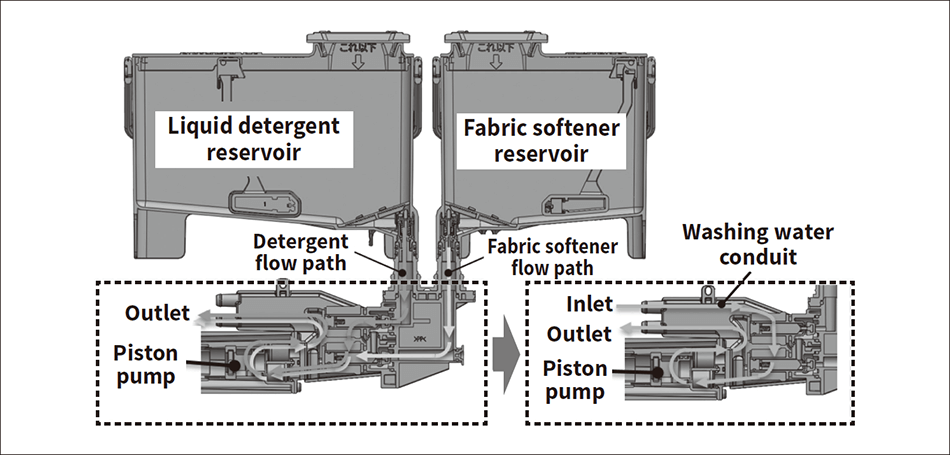

4.1 Development of Automatic Dispenser for Liquid Detergent and Fabric Softener

Along with eliminating the task of weighing out and adding detergent and fabric softener by dispensing it automatically, Hitachi also located the dispensing reservoirs at the front of the appliance for convenience. In doing so, the appliance was made even easier to use by relocating the control panel from the front to the top of the reinforced glass lid (top-opening) and installing it as a touch panel, making it is easy to see and operate (see Figure 12).

The reservoirs were made large enough (1,000 mL for liquid detergent and 700 mL for fabric softener) to accommodate the entire content of a refill pack. They are also self-contained units, designed so that they can be removed from the appliance and refilled separately.

Quantity control (to fulfill the core function of dispensing a reliable quantity of detergent or softener) and internal cleaning (important for ease of maintenance) are key requirements for the automatic dispenser. A piston pump that delivers a fixed quantity was selected to control how much detergent or softener is dispensed. As the pump delivers in 3-mL increments regardless of detergent type or other conditions, the total quantity is determined by the number of pump cycles. For internal cleaning, the design and operation of the dispenser allows for it to be flushed with clean water after dispensing detergent or softener to prevent clogging by residual liquid (see Figure 13). Total water use is kept the same as the previous BW-DV120C model (125 L) by discharging the water used for flushing into the tub where it is used for washing and rinsing, thereby avoiding waste.

4.2 Development of AI-based washing

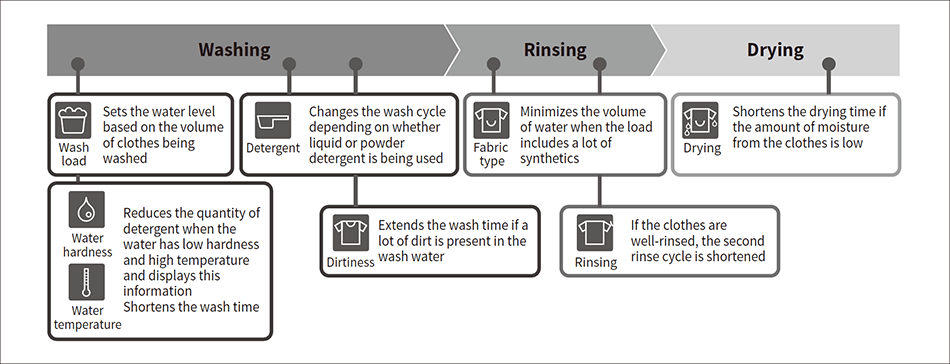

AI-based washing controls the wash cycle and duration automatically based on the clothes being washed and other conditions, using sensors to collect eight different items of information, including water hardness and water temperature, how dirty the clothes are, and detergent type (see Figure 14).

This includes being able to adjust the amount of detergent automatically based on the hardness and temperature of the water. As detergent is more effective when the water has low hardness and high temperature, for example, the quantity of detergent can be reduced without loss of wash performance under these conditions. Used in tandem with the automatic dispenser for liquid detergent and fabric softener described above, the system can control all the steps of determining how much detergent to use and then weighing it out and dispensing it.

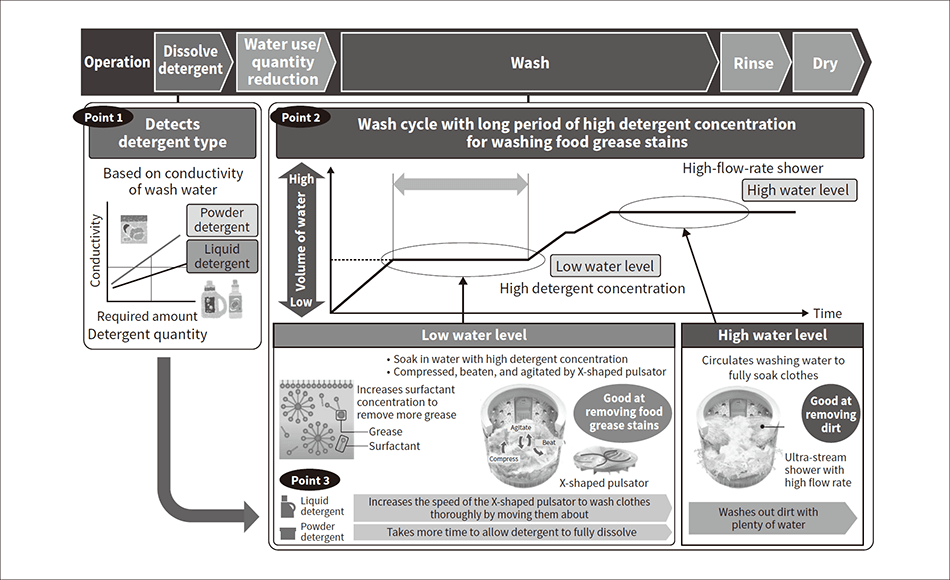

Another function distinguishes between different types of detergent and selects the wash cycle accordingly (see Figure 15). Detergent comes in two main forms: liquid and powder. The default wash cycles used in the past were the same regardless of detergent type. The new washing machine further improves the washing process by using differences in electrical conductivity to determine the type of detergent used and then operating in a way that best suits its particular characteristics.

The detergent is dispensed at the start of the wash and this is when the conductivity sensor in the tub identifies whether powder or liquid detergent is being used. As getting the detergent to dissolve is important when powder is used, the wash cycle begins by allowing time for this to occur before commencing the washing process. With liquid detergent, in contrast, the dissolving time is shortened, and the agitator speed is increased to keep the clothes moving around as they are washed.

The washing process is controlled in a way that is effective at removing both grease and dirt. First of all, dealing with grease requires that more of the surfactant in the detergent be absorbed into the stains. To achieve this, the water level is kept low to take advantage of the resulting high concentration of detergent in the washing water. Past practice, however, was to keep this part of the cycle short because of the risk of uneven washing from long exposure to high concentrations. The new model minimizes this problem of uneven washing by getting the high-concentration washing water to soak uniformly into the clothes, achieving this by showering them with water while spinning the tub to increase the spread of the water spray and more quickly dampen the clothes. Doing so improves grease removal by allowing a longer high-concentration soaking period. Similarly, dirt is washed out of clothes in the subsequent part of the wash cycle, which uses plenty of water with a high water level and shower flow rate. This sequence of steps results in better washing performance and reduces the effort of pre-washing or double-washing clothes. It is marketed by Hitachi as the “Ultra-Stream Wash.”

In this way, Hitachi has further automated clothes washing through a combination of sensing and control.

Fig. 14—AI-based Washing AI-based washing controls the appliance through the steps of washing, rinsing, and drying.

AI-based washing controls the appliance through the steps of washing, rinsing, and drying.

Fig. 15—Block Diagram of Ultra-Stream Wash Wash performance is improved by determining the type of detergent and changing the wash cycle accordingly.

Wash performance is improved by determining the type of detergent and changing the wash cycle accordingly.

5. Room Air Conditioner with Frost Wash Fan Robo

The requirements for room air conditioners, which have become essential for modern life, include not only energy efficiency, but also internal cleanliness.

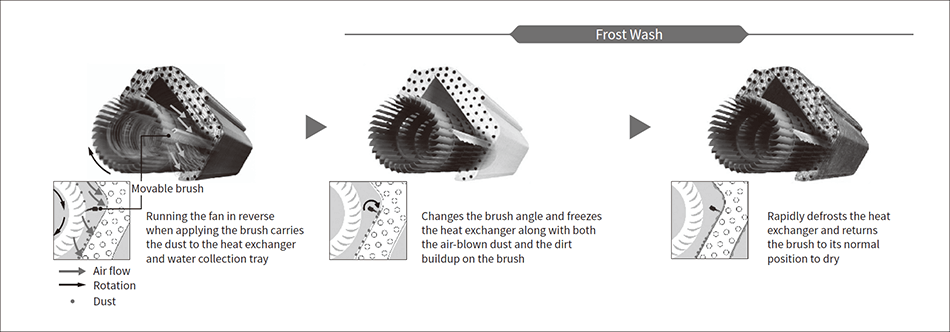

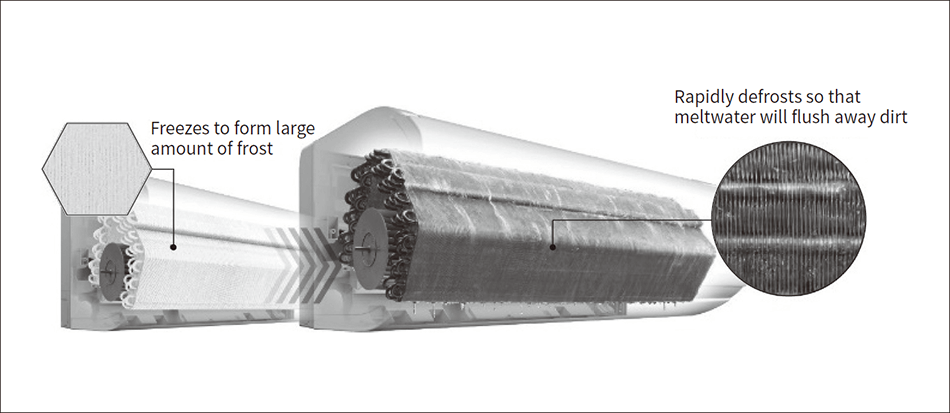

In 2017, Hitachi-Johnson Controls Air Conditioning, Inc. developed a new air conditioner with a “Frost Wash” feature that works year-round to clean the heat exchanger automatically, using the large amount of water obtained by first cooling it below freezing and then quickly defrosting it. The aim is to deliver fresh air by keeping the interior of the indoor unit clean without compromising energy efficiency (see Figure 16).

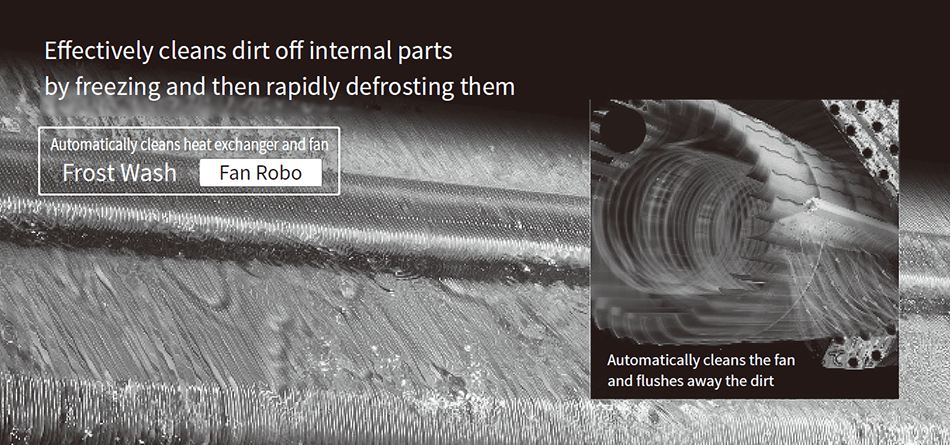

This was further enhanced in 2018 by the development of another internal cleaning method called “Frost Wash Fan Robo” that cleans off dirt from the fan in the indoor unit (see Figure 17).

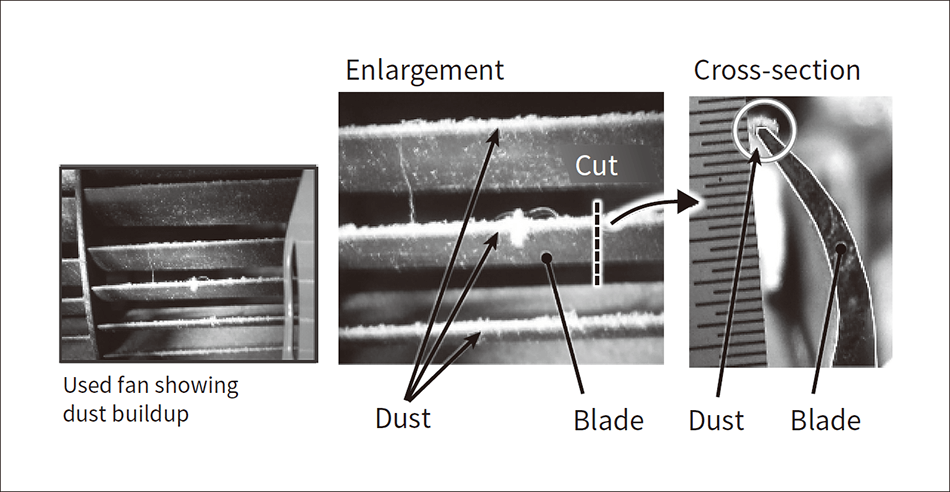

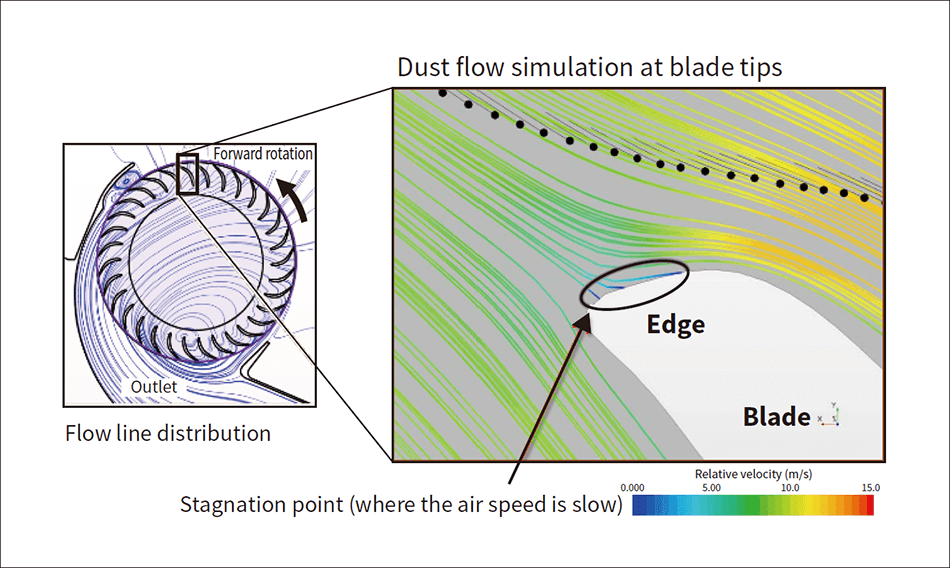

A fan that has been in use for a long time will exhibit a buildup of dust, especially on the blade tips (see Figure 18). To determine the mechanism by which this occurs, Hitachi used a dust flow simulation that represented the dust as particles and used fluid dynamics to analyze their movement. The way it happens is that fine particles are deposited on the blade at the stagnation point where the air speed over the blade tips is low, adhering and accumulating on the blade tips by static electricity and other means (see Figure 19).

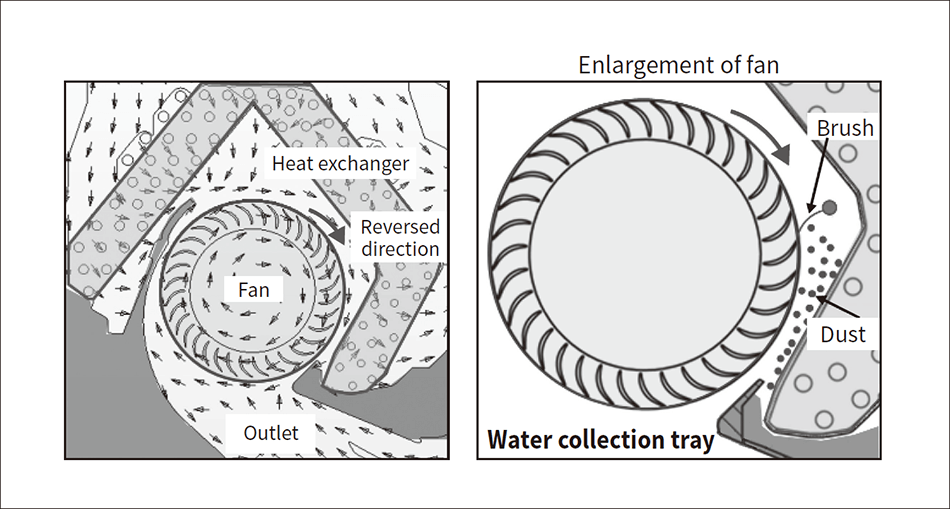

The design developed to clean dust from the blade tips does so by bringing the rotating fan into contact with a brush. The problem with this, however, is that the air from the rotating fan is normally expelled into the room and so risks carrying any removed dust with it. Their solution was to run the fan in reverse when applying the brush.

Simulation and flow visualization techniques were used to determine the air flow when the fan is run in reverse and the dust build-up on the heat exchanger. The results showed how the air flows in the opposite direction (from the outlet toward the heat exchanger) when the fan is reversed (see Figure 20). Based on this, a revolutionary new cleaning method was developed whereby the dust removed by the brush accumulates on the heat exchanger side where the Frost Wash function is used to flush it out along with the drain water (see Figure 21).

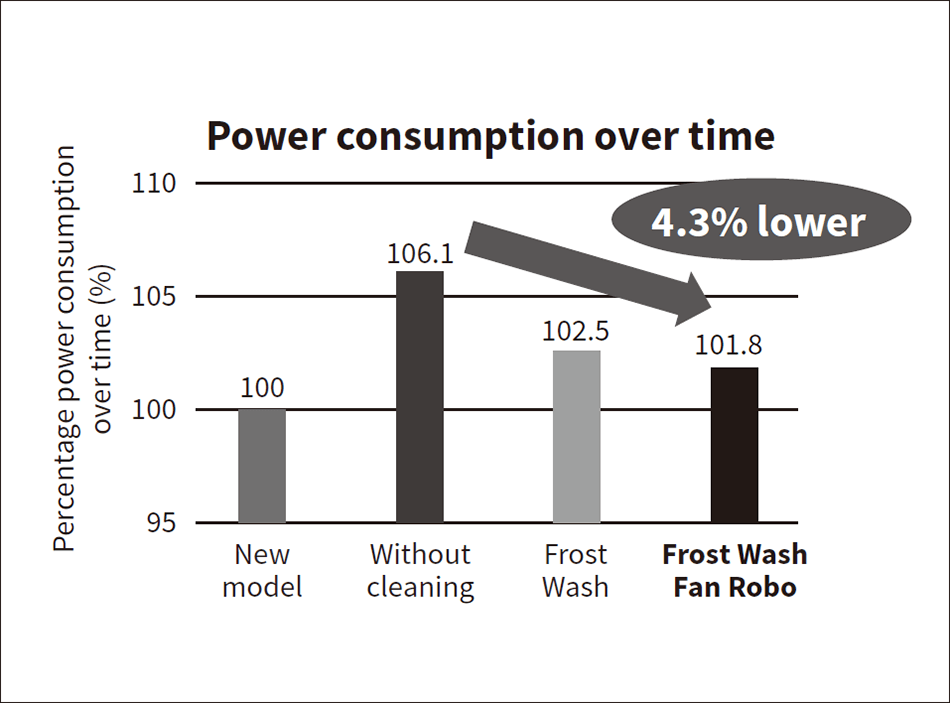

By keeping the fan clean, the Frost Wash Fan Robo feature also maintains fan performance and minimizes the loss of energy efficiency (see Figure 22).

In this way, use of analytical techniques to study what is happening in detail was used to develop automatic control for keeping the difficult-to-access internal components of the appliance clean.

Fig. 16—Frost Wash This cleans the heat exchanger by first lowering its temperature below freezing and then rapidly defrosting it.

This cleans the heat exchanger by first lowering its temperature below freezing and then rapidly defrosting it.

Fig. 17—Frost Wash Fan Robo This automatically cleans the fan, an internal component that is difficult to access.

This automatically cleans the fan, an internal component that is difficult to access.

Fig. 19—Dust Flow Simulation Dust accumulates and adheres at the blade tips where the air speed is slow.

Dust accumulates and adheres at the blade tips where the air speed is slow.

Fig. 20—Airflow and Movement of Dust when Fan is Run in Reverse The air flows in the opposite direction when the fan is reversed, causing dust to accumulate on the heat exchanger.

The air flows in the opposite direction when the fan is reversed, causing dust to accumulate on the heat exchanger.

6. Conclusions

This article has described the development of technologies for automation, ease-of-use, and customization that make housework easier and are suited to the growing diversity of lifestyles. It is anticipated that the demand for these will only grow in the future. Hitachi intends to continue enhancing its technologies for analysis, mechanical design, sensing, and control so that it can deliver new value in ways that suit individual needs.